Li-pluetse tsa carbide li-curbante tse sebelisoang ka har'a pompo e phahameng ea khatello ea maikutlo

Tlhaloso

Tungs Camde Plungere sebelisoa bakeng sa lipompo tsa khatello e phahameng hobane li-prunger tsa carbide li fana ka bokhoni bo botle bo loantšang likopano tse ntle, ho fihlela ho ba 500ppsi.

Likarolo tsa mantlha tsa Zhuzhou Chuangrui TungstenCarbide Plungerli na le thepa e matla ea mochini, e phahameng haholo khanyetsong ea ho hanyetsa le ho hanyetsa phahameng haholo.

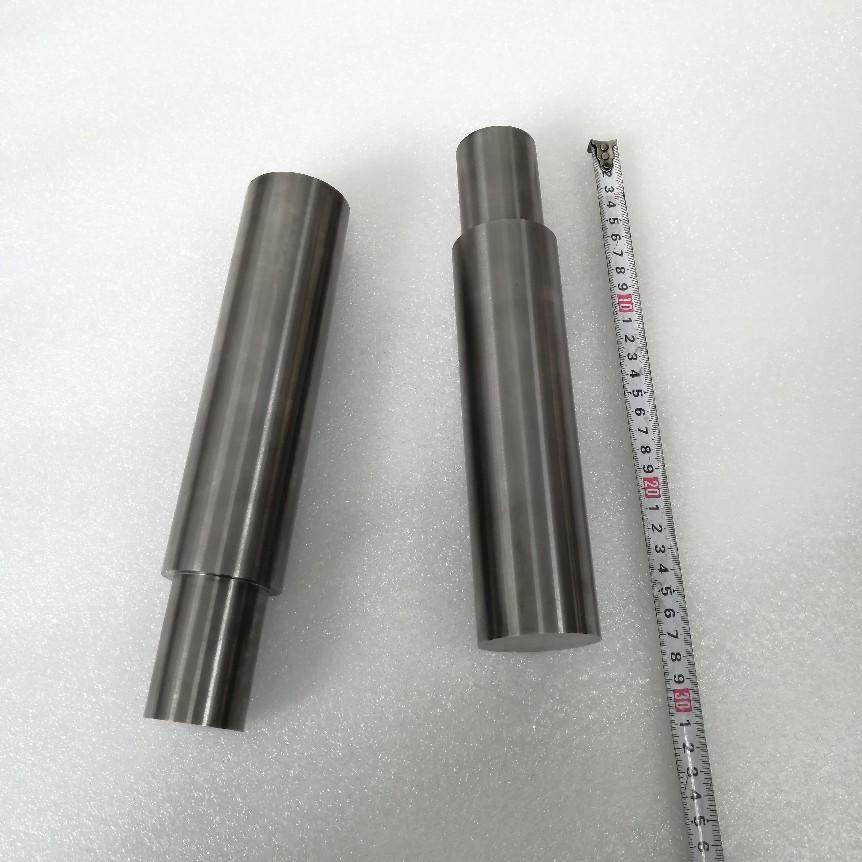

Mafuma a Chungrui a Chaangoi a fana ka boholo bo fapaneng ba li-pluck tse fapaneng tsa curbarten ka lisenthimithara.

Linepe

Li-plutlars tsa Tingsten tsa Tungas

Boholo bo boholo ba carbide plukeer rots

Carbide pluetse

Sekhahla sa Tingsten Tungasten oa Carbide

No-Magnet Tungasten Carbide Plunger

Carbisi Pistrons

Ho mamella ha carbide high-pRessure PUmp leqmatšoafo:

TheHo mamella ha carbide li-plungerske ntho ea bohlokoa ho nahana ka mokhoa oa bona oa merero le mokhoa oa thepa. Likopi tsa pompo ea khatello ea khatello e phahameng, mamello ea planta e tiile haholo, e sebelisoang hangata e lekantsoeng hangata ka li-minens.

Ts'ebetso ea ho etsa lihlahisoa bakeng sa likoloto tsa carbide e kenyelletsa ho fana ka mokhoa o nepahetseng ho fihlela mamello e hlokahalang.CNC Mechine ea CNC'Me mahlale a mang a fanang ka' mele o tsoetseng pele hangata a sebelisoa ho hlahisa li-pluiders tsa carbisi ka nepo le ho nepahala.

Ho tiea hoa hlokahala ho latela kopo e khethehileng le boemo ba ho hlaka ho hlokahala bakeng sa liphula ho sebetsa hantle ka har'a pompo. Ts'ebetso ea tlhahiso hangata e kenyelletsa ho tsamaisa thepa le maikutlo, khatello, le ho vibration li lokela ho hlahlojoa li-pluntars tsa Carbisi bakeng sa kopo e itseng.

Sehlopha sa carbide sa tungs:

BoholoLi-plutlars tsa Tingsten tsa Tungasli hloka hantle haholo ho roala ha li-plutuers li sebetsa pompong.Mahlale a RonaHo fana ka maikutloho sebelisoatungsten carbideCR8XKe 80000 ea 5000 pmi ho 40000psi. e 'ngoeCR15Xea sehlopha sa carbide carbide ke bakeng sa khatello e phahameng ho fihlela 100000. 'Mapa.CRNKereiti ke bakeng sa lits'ebetso tse khethehileng ha ho se makenete. TsohleCRNLi-carbids tsa tungs li na le makenete. Mophato lena o loketse bakeng sa mokhalase oa sejoale-joale.

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe