Sets'oants'o se seholo sa carbide se seholo

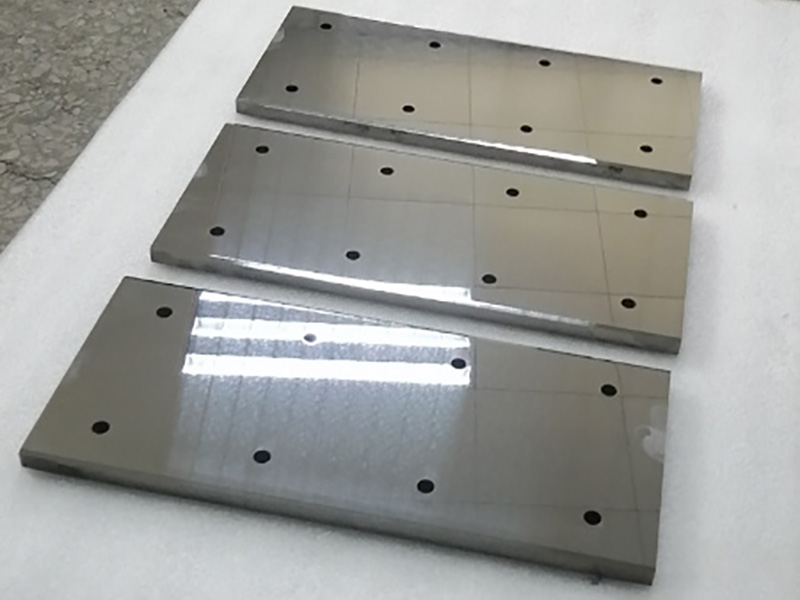

Tlhaloso

Lipolate tsa carbide carbide li entsoe ka wc le phofo ea cobaltrigg ke mekhoa ea metallirgy, e boetse e tsejoa e le li-trankten carbite li-block tsa cutesten. Lijana tsa Zhuazhou Chunted Carbide li fana ka lipolanete tse fumanehang ka holimo le tse thata tse tsamaellanang le li-spinid tsa carbide, li hatelle le ho theha moetsalibe, le tlhahlobo ea boleng. Molaki-leraba o fokotsa litšeho mme o eketsa letsoalo la lipolao tsa pokello tsa li-carbide tsa rona tsa carbide, li netefatsa boleng ba rona bo sa feleng. Ka nako e ts'oanang, ho hatella ha Istostatic ho etsa hore ntho e ts'oanang ea letsoalo. Re ka fana ka limaraka tse fapaneng, tse kang YW1, YT15, YG6X, ETC, le lits'ebeletso tse etselitsoeng ho latela litlhoko tsa hau.

Hobaneng u khetha thepa ea carbide ea tungsten?

Cartide e kopaneng e na le letoto la thepa e ntle e kang ho hanyetsa ka thata, haholo ho hanyetsa, matla a mocheso, e ntse e sa fetohe, 'me e ntse e le thata ho 1000. Ka hona, e sebelisoa ka bongata mochining. Melemo ea 'mele ea mafura a tungsten e bonyane makhetlo a 3 ea tšepe. E ka etsoa ka mefuta eohle ea lipolanete tsa carbisi.

Linepe

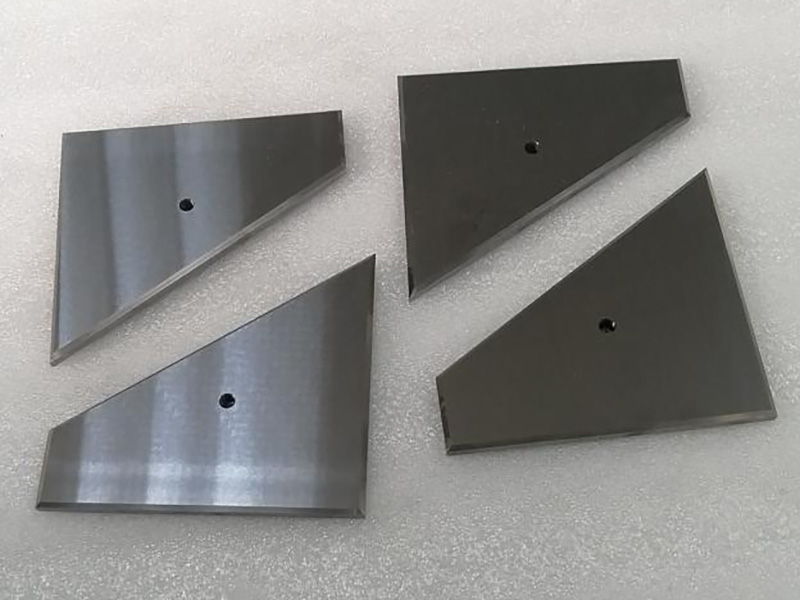

Plate ea Carbide e hlophisitsoeng

Pleten carbide Pletete ka lesoba

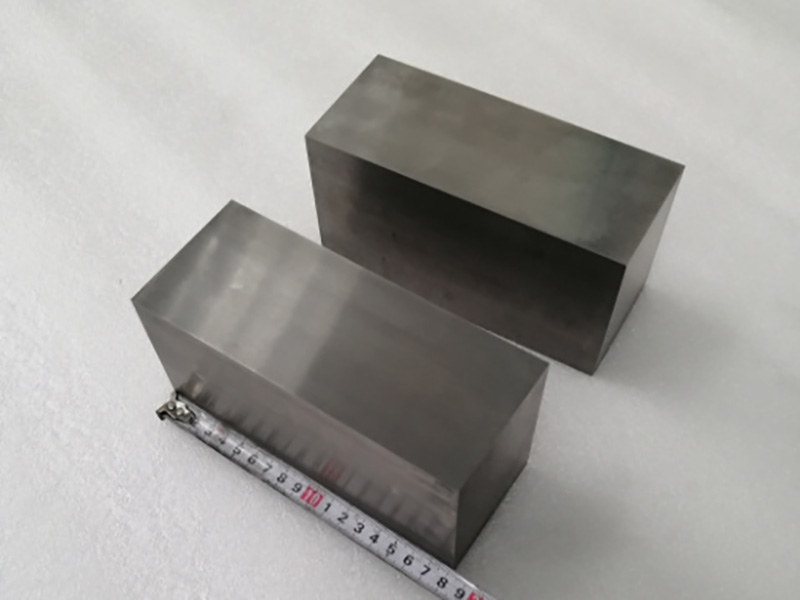

Tungas Caarbide Block

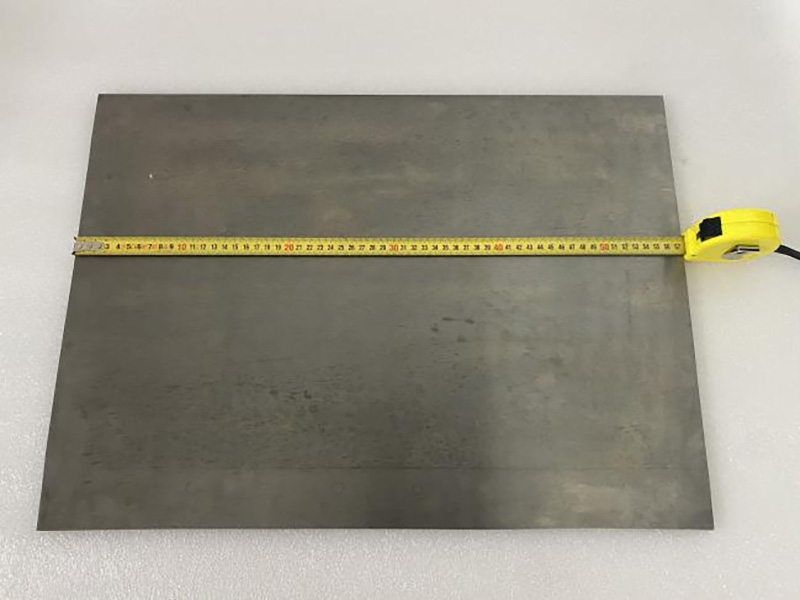

boholo bo boholo ba carbide clate

Carbide War Plete

Carbide Flat Bar

Leqephe la carbide carbide

Li-bars ba Carbide ba qetile

Carbisi Plata ea Mold

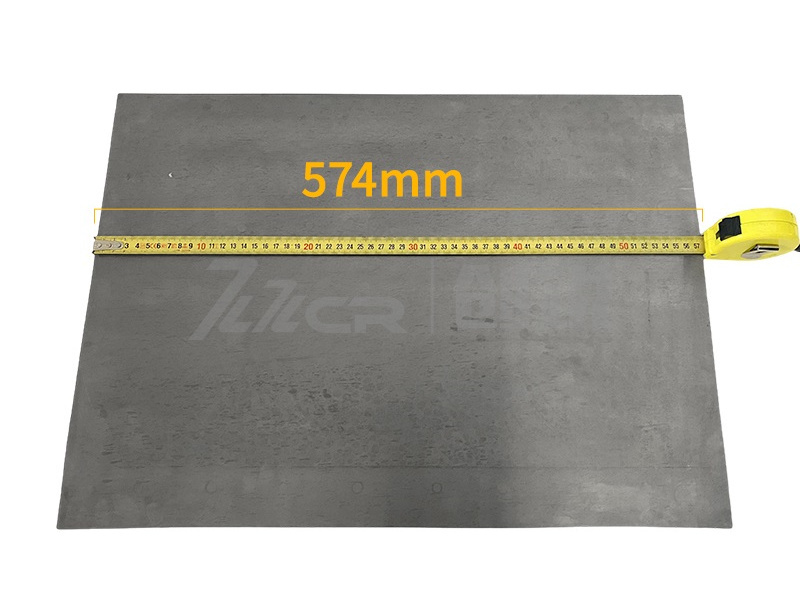

Tlhahisoleseling ea boholo: (OEM e amoheloa)

| Botenya (limilimithara) | Bophara (MM) | Bolelele (limilimithara) |

| 1.5-2.0 | 150 | 200 |

| 2.0-3.0 | 200 | 250 |

| 3.0-4.0 | 250 | 420 |

| 4.0-6.0 | 300 | 570 |

| 6.0-8.0 | 300 | 600 |

| 8.0-10.0 | 350 | 750 |

| 10.0-14.0 | 400 | 800 |

| > 14.0 | 500 | 1000 |

Fmpe ea rona e na le hlobo e fapaneng e ka itokollang litšenyehelo tsa hao, hape re itsamaela haholo, re iphapanyetsa poleiti e kholo ea koloi, joalo ka bolelele ba ho ikopanya le rona bakeng sa lintlha.

Likopo

Likolotlolo tsa Carbide tse arotsoeng joalo ka ha li sebelisoe, tse kopanang le lisebelisoa tse fapaneng, tse joalo ka litheolelo, joalo-roala indastering e latelang:

E sebelisoang bakeng sa ho etsa lisebelisoa tse tsoetseng pele tsa ho romellana melaetsa le li-dess tse tsoelang pele tsa mochini oa Velocity pher.

E sebelisoa bakeng sa ho rekisa indastering ea electoron, indasteri ea IC, le semicondtor.

E sebelisoang bakeng sa Hartication, sethala sa tatisitse, e leng seretse se tataisoang, Ei silicon Steels, le ho otlanya hlobo bakeng sa lisebelisoa le likarolo tse tloaelehileng.

Rea u amohela ho ikopanya le rona nakong efe kapa efe!

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe