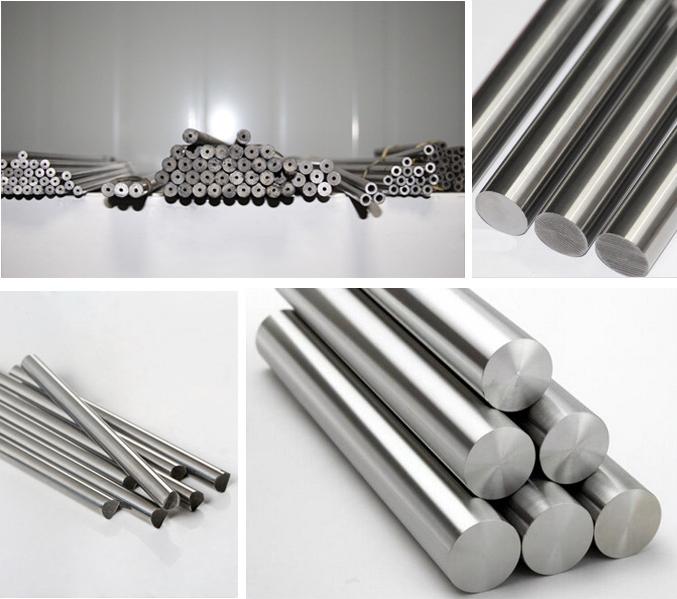

Ho na le mekhoa e 'meli e thehang bakeng sa tlhahiso ea tungsten carbide round Baa: Motho o qetetse,' me ho feto-fetoha le mokhoa o loketseng oa ho hlahisa mekoallo e telele ea ho hlahisa mekoallo e telele. E ka kenngoa ka bongata ba bolelele bofe kapa bofe bo lakatsoang ke mosebelisi nakong ea ho fela. Leha ho le joalo, bolelele bo akaretsang bo ke ke ba feta 350mm. E 'ngoe ke tšitiso ea tšoaetso, e leng mokhoa o loketseng oa ho hlahisa setoko se khuts'oane. Ha lebitso le bontša, phofo ea cardide ea Carbide e hatelloa ka sebopeho ka hlobo.

Carbisi e khutsitseng e na le letoto la thepa e ntle e kang ho hanyetsa ka thata, haholo ho hanyetsa, matla a mocheso, a ntseng a e-na le bothata bo boholo ho 1000. Majoe a cardide a sebelisoa hohle joalo ka lisebelisoa tsa lisebelisoa tse kang ho kuta tšepe, e nang le tšepe, tšepe e thata, tšepe e thata. Mill, motsoako oa khabise, ea ho omisa ka boomo, ea hatellang (ka khatello ea litšila kapa e sentse e kopaneng

Lisebelisoa tse tala li ntse li lekoa, li omella, li-dlue, li omella le khatello ea maikutlo, 'me qetellong li theha alloy e anyesang le ho seballoa.

Bothata ba tlhahiso ea barger baxr boxtrusion ke hore potoloho ea tlhahiso e telele. Senya li-suryeter tse nyane ka tlase ho 3mm le ho roba lipheletso tse peli li tla senya thepa e itseng. Bolelele ba bolelele ba bophara ba bophara ba kobo ea chebisithara bo pota-potileng bo bong bo otlolohileng ba se nang letho. Ehlile, mathata a hooatla le a chisi a ho potoloha a ka ntlafatsoa ka ho sisinyeha ha cyliving sethaleng.

E 'ngoe ke tšitiso ea khatello ea khatello, eo setoko se sengoaneng sa Bar se hlahisoang ke. Joalokaha lebitso le bontša, ke hlobo e hatellang phokotso ea carmente e halikiloeng e be sebopeho sa car. Monyetla oa ho theha mokhoa oa ho theha mokhoa ke hore o ka thehoa ka ho fetisa ha motho a le mong ebe o fokotsa ho kuta. Fokotsa ts'ebetso ea terata le ho felisa potoloho e omileng ea mokhoa o sa khaotseng. Nako e khutsufalitsoeng e kaholimo e ka pholosa bareki matsatsi a 7-10.

Ha e le hantle, ho hatella ha khatello ea maikutlo haholo le hona ho bohlokoa ba ho bopa. Ho hatella ha Istostatic ke mokhoa o nepahetseng oa ho theha bakeng sa tlhahiso ea carbide e melelele ea carbide e pota-potiloeng. Ka litisetso tse holimo le tse tlase tsa Plistory, pompo ea khatello ea khatello ea metsi le rabara e thata, 'me khatello e fetiselitsoe ho etsa phobi ea carmente e halikiloeng e hatelletsoeng ho theha.

Nako ea poso: Jan-24-2024