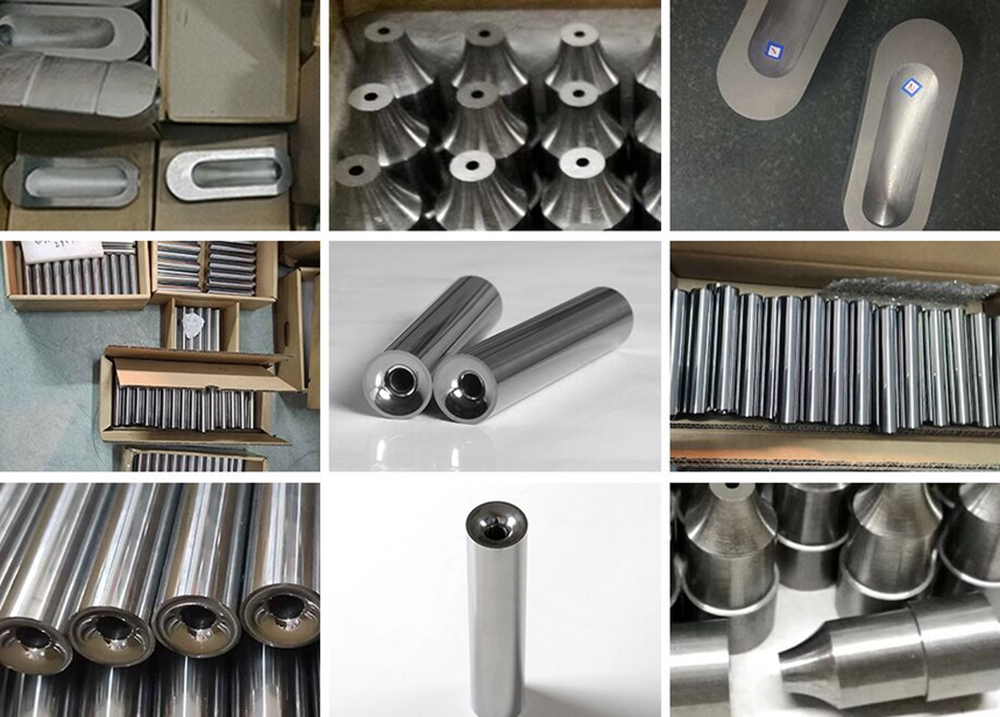

Khafetsa re bona karolo e nyane indastering ea tlhahiso - leha ho le joalo, leha e le hore e nyane ke karolo eo re ke keng ra e hlokomoloha. Li-nozzles tsa indasteri li sebelisoa ka thata ho fafatsa, ho fafatsa, ho fafatsa, ho fafatsa le ho fafatsa le ho bapala le lisebelisoa tse ling le ho bapala karolo ea bohlokoahali. Ho hlakile hore thepa ea se nonyang e kenyelletsa carbide ea tšepe, likhoebo tsa kotara, li theko e phahameng, 'me ho se bonolo ho li apara. Kajeno, mohlophisi oa Chuangrui o tla u tsebisa tšebeliso ea hau e tloaelehileng ea li-nobide tse halikiloeng.

Carbide bakeng sa sandblas

Li-nogazles tsa carbiside ke karolo ea bohlokoa ea lisebelisoa tsa lehlabathe. Lisebelisoa tsa sandbla tsa sandblate li tsamaisoa ka moea o hatelletsoeng, 'me o hlophisa boitsebiso bo ka holim'a metsi ka lebelo le phahameng ho fihlela sepheo sa kalafo. Ha ho bapisoa le li-nozle tse entsoeng ka thepa e meng, joalo ka li-nozzles tse ngata, matla, ho hanyetsa ha carbide, 'me li ka kopana le litlhoko tsa maemo a kopo.

Carbiside nozzles bakeng sa ho cheka oli

Ts'ebetsong ea ho ema, hangata e le tikolohong e mpe, kahoo nozzle e hloka ho mamella tšusumetso e phahameng ea liprofinse tse phahameng nakong ea ho sebetsa, e tloahelang ho khathala le ho se atlehe. Lisebelisoa tse tloaelehileng li tloaetse ho fokotsoa ke Deformal kapa ho lisa, 'me bofe-morao li hloka ho nkeloa sebaka khafetsa, tse fokotsang katleho ea mosebetsi. Li-nogzles tsa carbide li ka ntlafatsa boemo bona ka lebaka la thata le phahameng, matla a phahameng le ho itšireletsa hantle le ho itlhorisa.

Carbide nozzle bakeng sa cws

Ha nozzle ea metsi a mangata a phollama ea mashala a sebetsa, haholo-holo khohoneng e tlase ea mashala ea mashala ea mashala, 'me boholo ba ho roala haholo le ho itšeha. Ha ho bapisoa le li-cors nozzles tse ling tsa tšepe, tse halikiloeng tse bokelletsoeng ho roala khanyetso le khatello ea tšebeletso (hangata ho feta 1000h). Leha ho le joalo, le ile la phuthoa, ho thatafala ha koloi, ho hanyetsana le ho tsitsipana le ho makala ha ho bonolo ho sebetsana le lisebelisoa le sebopeho se rarahaneng.

Carbide atomaise nozle

Mefuta ea athomano ea li-carbide tse halikiloeng e ka aroloa ka tatellano ea khatello, atohotenation ea motlakase, athonic athonic attoniction le bumble athonic. Ha ho bapisoa le mefuta e meng ea li-nozzles, nozzles e halikiloeng e ka fihlela phello e fafatsa ntle le compressor ea moea. Sebopeho sa mokhoa oa ho ikatisa ka kakaretso ke bopehileng ba fan,, ka phello e ntle ea atomination le tšireletso e ngata. E sebelisoa ho tlhahiso ea temo ea temo ho fafatsa le ho fafatsa indasteri. E sebelisoa haholo ka ho fafatsa, ho tlosa lerōle le tlokotsi ho tlhahiso.

Chuangru e qalile ho ntlafatsa lisebelisoa tse fapaneng ho ntlafatsa lisebelisoa tsa ho hanyetsa le ho ikhula thepa, 'me u fa bareki mefuta e fapaneng ea lithaelese le litšenyehelo tsa litšenyehelo tsa ho sebetsa. E na le theknoloji ea ho ntlafatsa le ho fana ka tlhahiso ea tlhahiso e khutsitseng, e tsamaisanang le mela e ikemetseng le e ikemetseng. Haeba u na le litlhoko tse nepahetseng, ka kopo ikutloe u lokolohile ho ikopanya le rona.

Nako ea poso: Mots'eanong-31-2023