MWD & LWD likarolo tse tungsten carbide popepture qetellong le orifice bakeng sa lisebelisoa tsa ho taka

Tlhaloso

TheTungans carbide poppet QETABakeng sa MWD le LWD e sebelisoa haholo bakeng sa ts'ebetso ea ho fufuleloa, ho tsitsipana ho tsitsipana, ho pharalla ha phallo le tlhaiso-leseling e ngoe. Koloi ea Khotso ea Tungas Valve ke e 'ngoe ea tsona e sebelisitsoeng MWD le LWD. Lintlha tse fapaneng tsa thuto ea bohlokoa tse ka sehloohong li ka hlahisa matšoao a fapaneng a khatello, ho bonolo ho fetola matla a khatello ea khatello ho latela maemo a khatello, tebileng le mabaka a mang hantle.

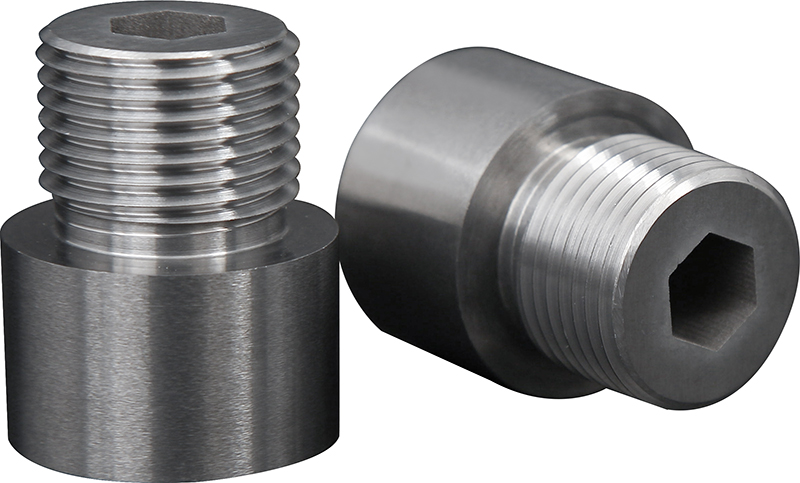

Fektheri ea rona e sebelisang lisebelisoa tsa boleng bo holimo ho hlahisa ntlha ea poppet. Ntlafatsa matla a ho beleha le bophelo bo tepellang ba koloi ea carbide.

Ts'ebetso ea rona ea ho qetela ea CCN e qetellang ea CCN e etsa bonnete ba hore pheletso e 'ngoe le e' ngoe e entsoe ka mokhoa o hlakileng. Mokhoa ona o laoloang ke mechini o laoloang ke likhomphutha o tiisa boholo bo feto-fetohang, lits'ebeletso tse boreleli, 'me li na le mapolanka,' me ho mamella sehlahisoa se amanang hantle.

Paramente

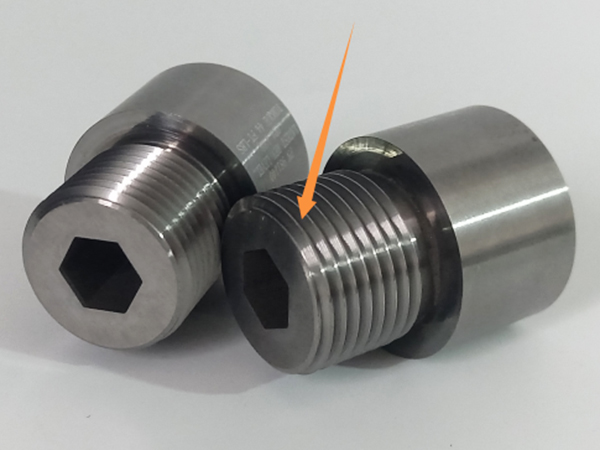

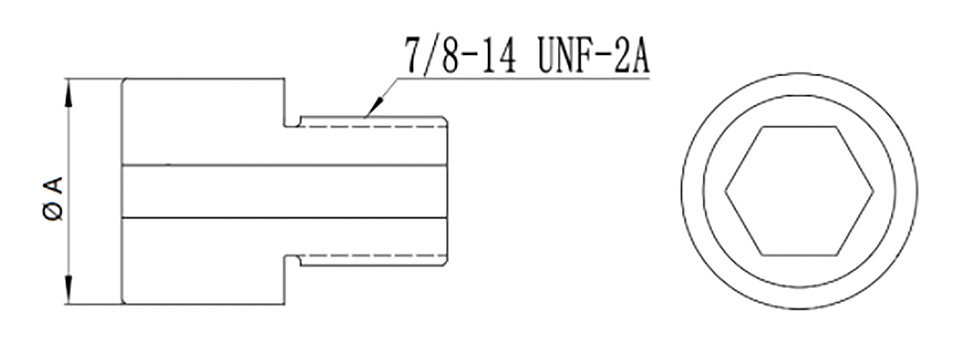

Pheletso ea poppet e entsoe katungsten carbideBoitsebiso bo.the 7 / 8-14 karolo e tlokotsing ea poppet e tsoela pele ka kotloloho e sebelisa mechini ea CNCON. Ts'ebetso ena ea ho etsa lintho tse hlokoang ka tlhokomelo e tiisang e tiisa ho nepahala ka ho fetisisa le ho tiea ha ho khokhothela. Ka boemo bona ba ho nepahala, o ka tšepa hore popepo e 'ngoe le e' ngoe e ka e-ba teng ka litlhoko tsa hau tse tahang. Bopaki bo nang le boiphihlelo bo ka netefatsa hore poppete e loketse lisebelisoa tsa hau.

Laser Marking bakeng sa netefatso ea boholo bo potlakileng le botsitso.

Litlhaloso

Motsoako oa popero oa carbide

| Ntho | Boholo bo boholo | Khoele |

| 981213 | Ø1.0866 '' | 7 / 8-14 unf-2a |

| 98121414 | Ø1.040 '' | 7 / 8-14 unf-2a |

| 981140 | Ø11122 '' ' | 7 / 8-14 unf-2a |

Ka likhetho tse fapaneng tsa boholo bo fumanehang, ho tloha od1.086 '', 1.040 '' ', re ka amohela ho etsoa ho ea ka litlhoko tsa moreki. Mme ho feta, o ka fumana se loketseng hantle bakeng sa litlhoko tsa hau tsa sesebelisoa.

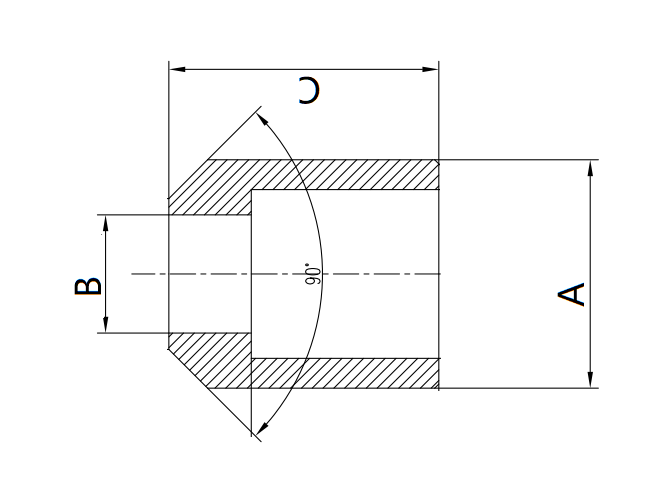

Malebela a carbide Poppet P360

| Ø | Øb | Øc |

| 1.04 '' | 0.57 '' | 1.30 '' |

| 1.086 '' | 0.57 '' | 1.30 '' |

| 1.125 ' | 0.57 '' | 1.30 '' |

| 1.16 '' | 0.57 '' | 1.30 '' |

Pompo ea carbide poppet e meng e tjena:

| Limaraka | LITLHAKISO TSA 'Mele | Kopo e kholo le litšobotsi tse kholo | ||

| Ho thata | Letsoalo | TRS | ||

| HRA | g / cm3 | N / mm2 | ||

| Cr35 | 88.5-89.5 | 14.30-14.50 | ≥2800 | E loketse ho hlahisa mekotla ea boroko le masela ka lebaka la mathata a maholo le ho hanyetsa botle bo phahameng, |

| CR06n | 90.2-91.2 | 14.80-15.00 | ≥2560 | E loketse ho hlahisa marikho le mahaeng a sebelisoang indastering ea oli le ea khase ka lebaka la ho hanyetsa se seholo sa litoropo le khoholefo |

Melemo ea rona

● Nakoana le ka ho fana ka nako

● Karolo e kholo e laoloang

● Ho khathatsa ho hanyetsa hantle

Litšebeletso tsa Rona

● Setifikeiti sa sehlopha

● Karolo le teko ea lintho tsa nama le tumello

● Ho hlahlobisise maikutlo ho fumaneha

O kanna oa rata

Poppett Timp

Booster selikalikoe

Serto Orific Louter

Khafetsa 350/650 Pulser Orifice

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe