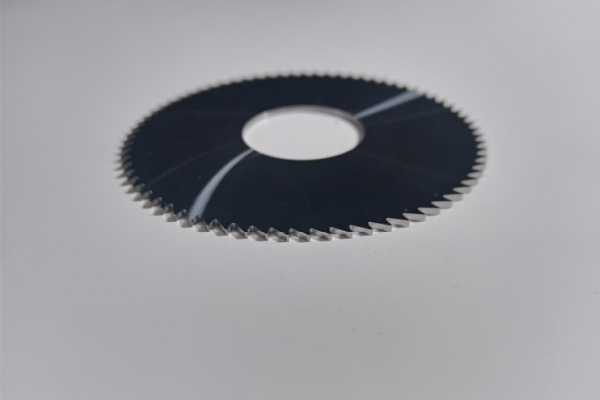

Seteishene se tiileng sa carbide se ile sa bona blade

Tlhaloso

Carbide e tiile e ile ea bona blads polasetiki le pvc board, tšepe eohle e sa lefelloeng, joalo ka Titanium, e se nang letsoai, joalo ka Titanium, Bronze, Aluminium le koporo.

E fana ka sephetho se hlakileng haholo ke leboha hore e matlafatse le likotsi tse ntlafatsang ho tšoarella ha eona le ho hanyetsa.

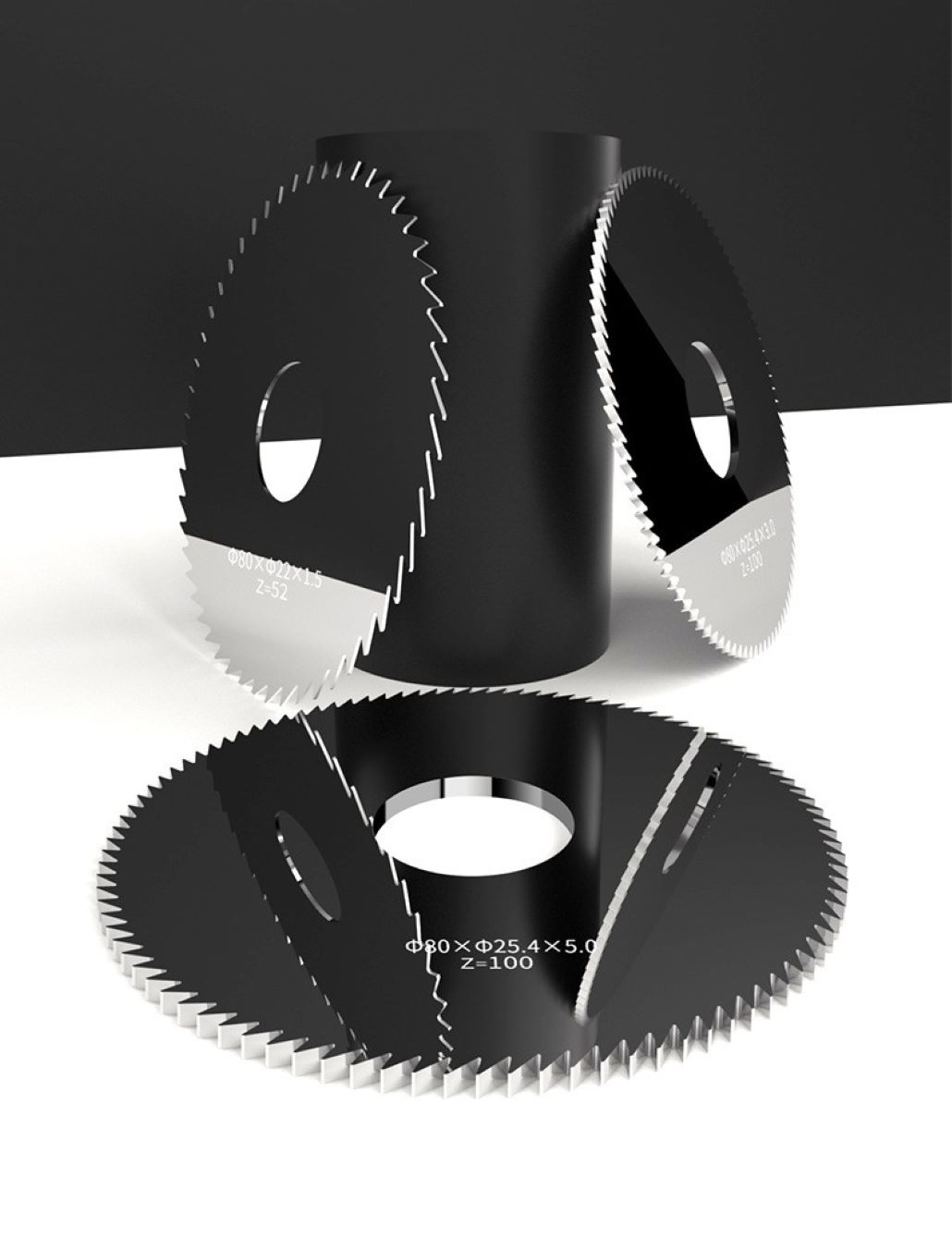

Likaroloana

● 100% CARIGHTIT TANGSTER LITLHAKISO TSA BOPHELO

● Tride ea Tee ea Diree e fumaneha

● Boholo bo fapaneng le ho ikoetlisa bakeng sa kopo e 'ngoe le e' ngoe

● Ho kuta maikutlo le ho tšoarella

● Ho ikamahanya le maemo le ho se sebetse

● Litheko tsa tlholisano

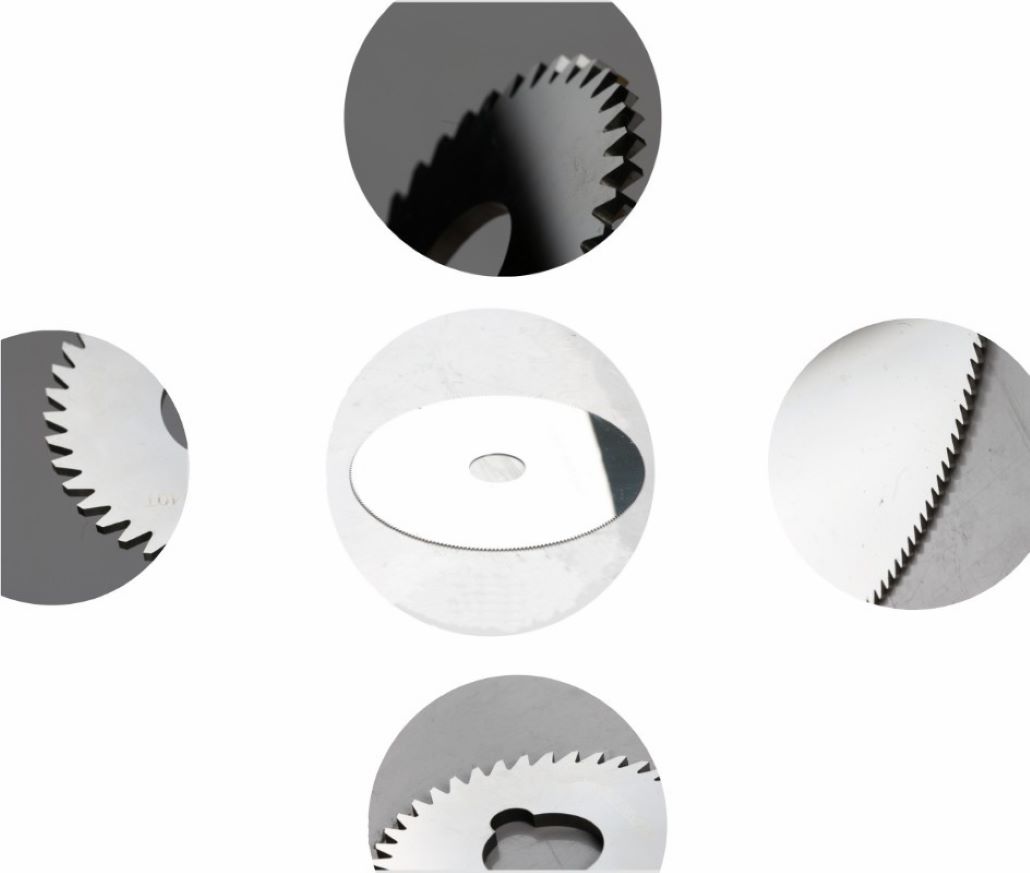

Linepe

01Sehiloeng se koetsoe

Ho hokela ho tebileng le ho nolofatsa.

Tšusumetso ea seipone ho ntlafatsa ho seha ts'ebetso.

02 PUSELETSO TSE KHOLO

Ho bona lehare ke boima bo phahameng le ho unyesa.

E theko e boima haholo.

03 Nako e telele ea bophelo

Tšebeletso ea bophelo bo bolelele, ho nepahala ebile ho na le kahlolo e hlohlelletsang eona.

04Patlisiso ea Saense

Ho itšeha hampe, ha ho bareki, ha ho na kotlo.

05 OEm

Ho se sebetse hantle ka mokhoa o seng molaong.

Monyetla

1.Aover lilemo tse 15 tsa ho etsa boiphihlelo ba ho etsa lintho tse ncha le lisebelisoa tse tsoetseng pele le theknoloji.

2. Ho nepahala ho phahameng, ho khaola ka potlako, ho hloka botsitso le ho sebetsa ka mokhoa o tsitsitseng.

3.Ha vindisher baipone ba siling. Lithapo tse tlase le boleng bo phahameng haholo li tiisa hore ho se uhiloe haholo

ts'ebetso le mokhoa o molelele oa lisebelisoa.

4. Lumella lebelo le phahameng le phahameng le litheko tse ngata le tlhahiso e phahameng. Bophelo ba bona ba bophelo bo eketsehile haholo.

Setsebi sa tloaelo eo e seng ea tloaelo e khethehileng ho latela setšoantšo sa bareki, boholo le tlhoko.

Kopo

E loketseng ho kopana le liphephetso tsa Metalductical kapa lialoro tsa koloi, e na le likarolo tse ling tsa kopo. Sebaka sa carbide se ile sa bona blade e lumella maemo a phahameng a ho khaola.

Ka lebaka la tlhaloso ea ho khaola lits'oants'o tsa hau, sehlopha sa rona se khona ho hlophisa litulo tsa carbide ho se lekanang hantle le phephetso e ngoe le e ngoe ea khoebo.

Ka lebaka la sehlopha sa rona sa tekheniki, re na le sesebelisoa seo u se hlokang.

Taolo ea rona ea boleng

Leano la boleng

Boleng ke moea oa lihlahisoa.

Taolo ea tšebetso ka kotloloho.

Zero o mamella bofokoli!

Ho fetisa setifikeiti sa Iso9001-2015

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe