Tungas carbide Comparren Plunger e sebelisoang ka indasteri ea oli le khase

Tlhaloso

CLENDID PUNGER PUNGERli sebelisoa ho Hyper Compressors ho hatella khase ea Ethylene ho hatella khatello ea Moputso. Sena se hloka boitsebiso bo hanyetsanang bo kopanyang thepa e hlokahalang ea ho kopanya le ho roala ha maemo a boima. Boitsebiso feela bo nang le thepa ena bo kopantsoe le carbide e halikiloeng.

Linepe

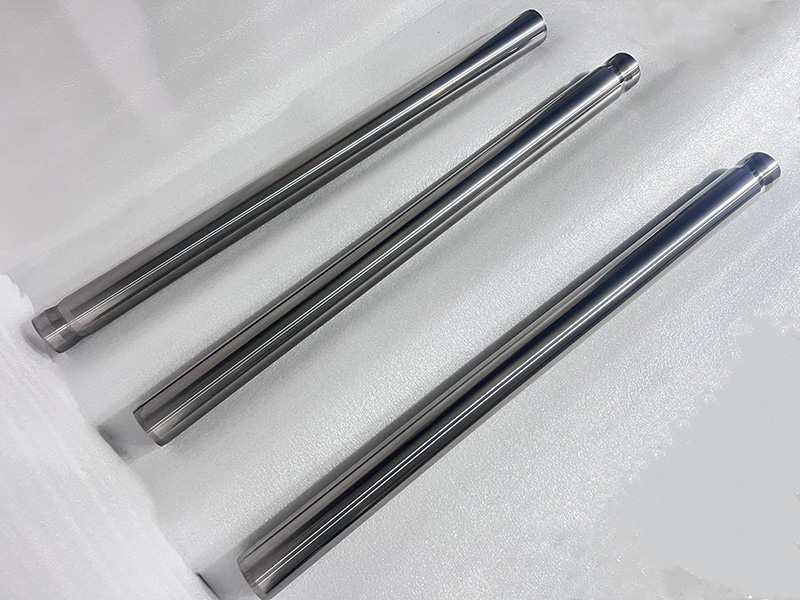

Li-plutlars tsa Tingsten tsa Tungas

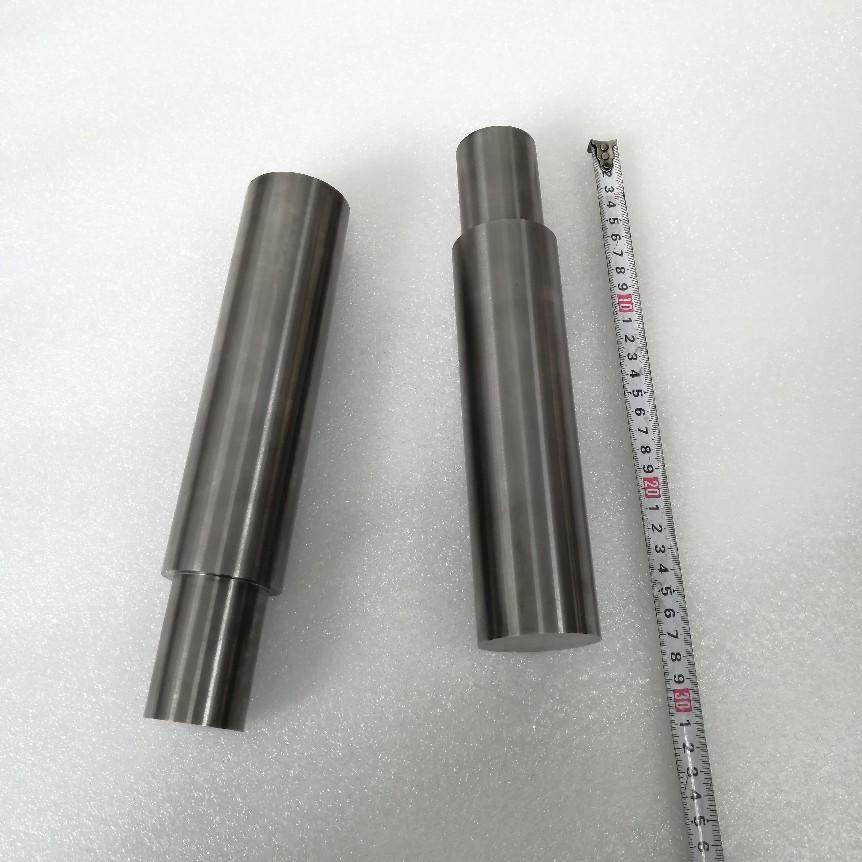

Boholo bo boholo ba carbide plukeer rots

Carbide pluetse

Sekhahla sa Tingsten Tungasten oa Carbide

No-Magnet Tungasten Carbide Plunger

Carbisi Pistrons

Monyetla

1. Ho feta lilemo tse 15 tsa ho kenya boiphihlelo ka lisebelisoa tse tsoetseng pele le theknoloji.

2. Ts'ebetso ea Lihlahisoa tsa Netefatso, boloka nako e eketsehileng le katleho ea mosebetsi.

3. Sehlopha se loketseng ka ho fetisisa sa carbide se ka etsoa bakeng sa kopo e 'ngoe le e' ngoe.

4. Etsa boleng bo phahameng le bo fetohileng.

Likaroloana

1. Ho thata haholo 'me u apare khanyetso:

- Tungs Carebide ke e 'ngoe ea thepa e thata ka ho fetisisa e fumanehang, e etsa hore e be e loketseng lits'ebetso tsa khatello e phahameng moo ho roala e le ntho e bohlokoa haholo.

- E boloka sebopeho sa eona le ho qeta nako le eona ho qeta nako e telele.

2. Matla a nang le khatello e phahameng:

- Tungnseten carbide e ka mamella likhatello tse feteletseng tse hlahisoang ke li-deminpher tsa hyper ntle le ho fokola kapa li hlohlelle.

3. Phetoho ea Corrosand:

- E loketse likhase tse tsamaisang litlolo tse tsamaisoang le lik'hemik'hale tsa lik'hemik'hale tse tloaelehileng ho hyper compressers.

4. Ho tsilatsila hoa futhumatsang:

- li-pluide tsa carbisi li ka sebetsa ka nepo mochesong o phahameng, o ka hlahisoang khafetsa nakong ea khatello ea khatello e phahameng.

5. Bophelo bo telele ba tšebeletso:

- Fokotsa litšenyehelo tsa phomolo tsa phomolo le tsa ho lokisa, joalo ka li-plulung tsa carbisi nako e telele ho feta lisebelisoa tsa moetlo joaloka tšepe.

Kopo

Indasteri u sebelisa lintlafatso tsa hyper ka li-pluetse tsa carbide

- indasteri ea Petrochemical: Bakeng sa llpe le tlhahiso ea HDP.

- Lihlahisoa tsa lik'hemik'hale: Bakeng sa li-synthes tse matla tsa lik'hemik'hale.

- Lekala la matla: Bakeng sa compression le polokelo ea hae.

- Patlisiso le nts'etsopele: Bakeng sa liteko le liteko tse phahameng haholo.

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe