Hungsten Carbiide Kigings

Tlhaloso

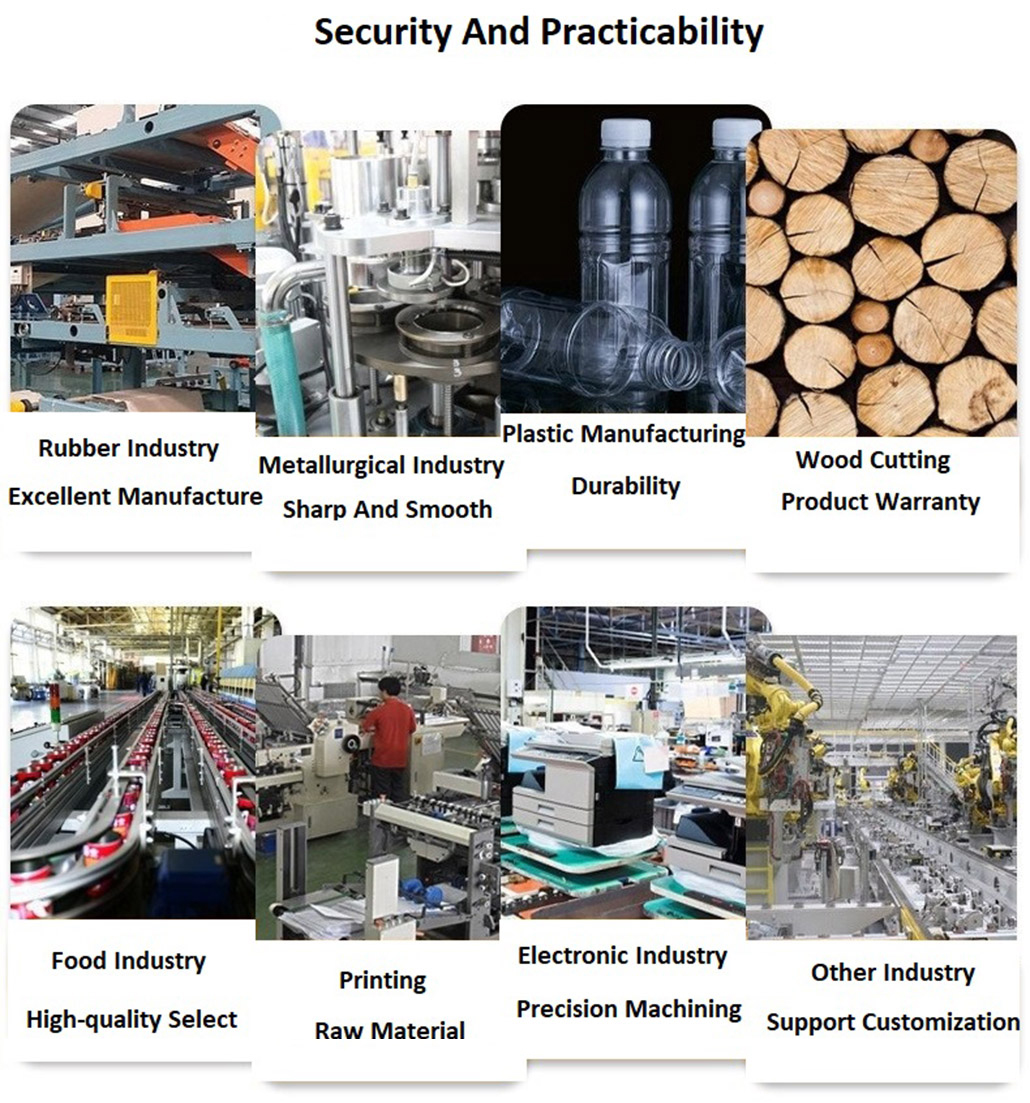

Hungsten carbide - le li-blades tsa tungs ka thata le ho roala khanyetso, boholo bo hlophisitsoeng le sehlopha se amohelehang. E sebelisitsoeng indastering e mengata, joalo ka betri, betri ea betri ea tšepe, ho sebetsa ha tšepe, kalafo ea kalafo joalo-joalo.

Likaroloana

• Lisebelisoa tsa pele tsa carbide tsa pele

• Ho fana ka tiiso ea mochini le tlhokomeliso ea boleng

• Boloka lehare le bohale bakeng sa ho tšoarella halelele

• Litšebeletso tsa fektheri ea litsebi le lihlahisoa tse sebetsang tse theko e tlaase

• boholo bo fapaneng le boholo ba kopo e 'ngoe le e' ngoe

Keletso ea li-tluesten carbide liliba le lehare

| Keletso | Boholo ba lijo-thollo | CO% | Hardness (HRA) | Mabenyane (g / cm3) | TRS (N / MM2) | Kopo |

| UCR06 | Ultrafine | 6 | 93.5 | 14.7 | 2400 | Ultrafine oltrafine o tlala ka thata e phahameng le ho roala mefuta ea mefuta ea likarolo tse bakileng tlasa maemo a tlase a ho etsa. |

| UCR12 | 12 | 92.7 | 14.1 | 3800 | ||

| Scr06 | Submicron | 6 | 92.9 | 14.9 | 2400 | Submicron Alloy Moterensenth e nang le thata e phahameng mme o rorisoe ke mefuta ea likarolo tsa indasteri e khaotsoeng tlasa maemo a tlase a sithabetsang. |

| SCR08 | 8 | 92,5 | 14.7 | 2600 | ||

| Scr10 | 10 | 91.7 | 14.4 | 3200 | Submicron Alloy Moterenteng e phahameng le ho ba thata haholo, e loketse lisebelisoa tse fapaneng tsa tšimo. | |

| Scr15 | 15 | 90.1 | 13.9 | 3200 | ||

| McR06 | Metsi a mahareng | 6 | 91 | 14.9 | 2400 | Mokhatlo o mahareng o nang le thata o phahameng mme o tšoeroe ke lintho tse sehiloeng tsa ho khaola tsa indasteri le lits'ila tse hatellang tlasa maemo a tlase a tlhoethi. |

| McR08 | 8 | 90 | 14.6 | 2000 | ||

| McR09 | 9 | 89.8 | 14.5 | 2800 | ||

| Mcr15 | 15 | 87.5 | 14.1 | 3000 | Mokhatlo o mahareng o nang le ho ba thata haholo o nang le matla a ho khaola a ho khaola le ho sithabetsa maikutlo tlas'a maemo a tebileng. E na le ho tsitsipana le ho hanyetse. |

Sehlahisoa se seng o kanna oa rata

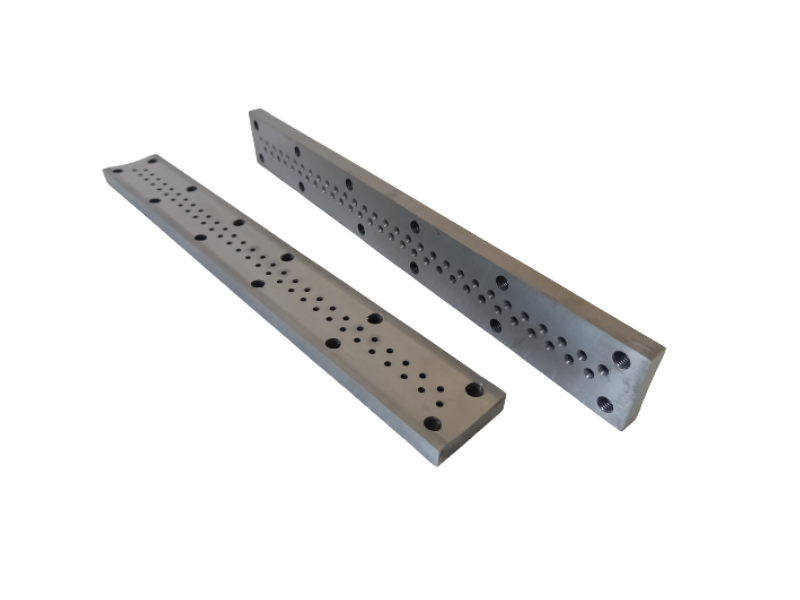

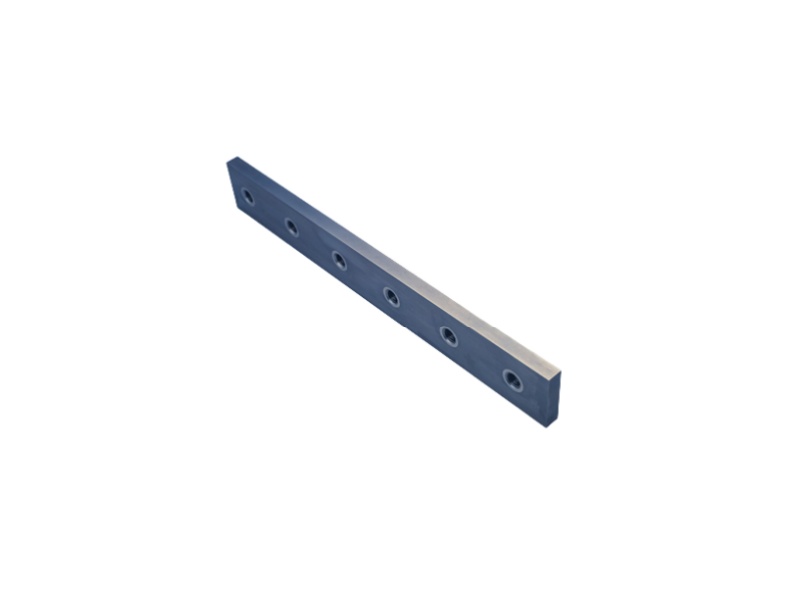

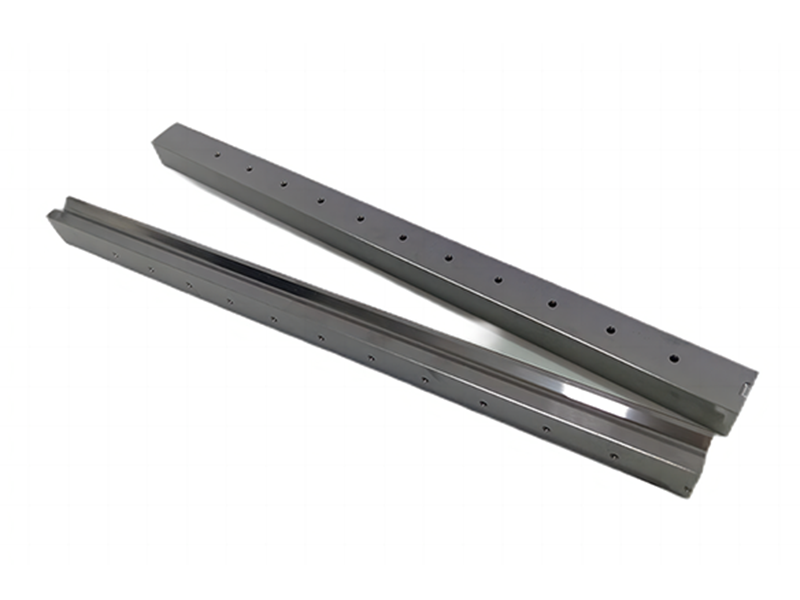

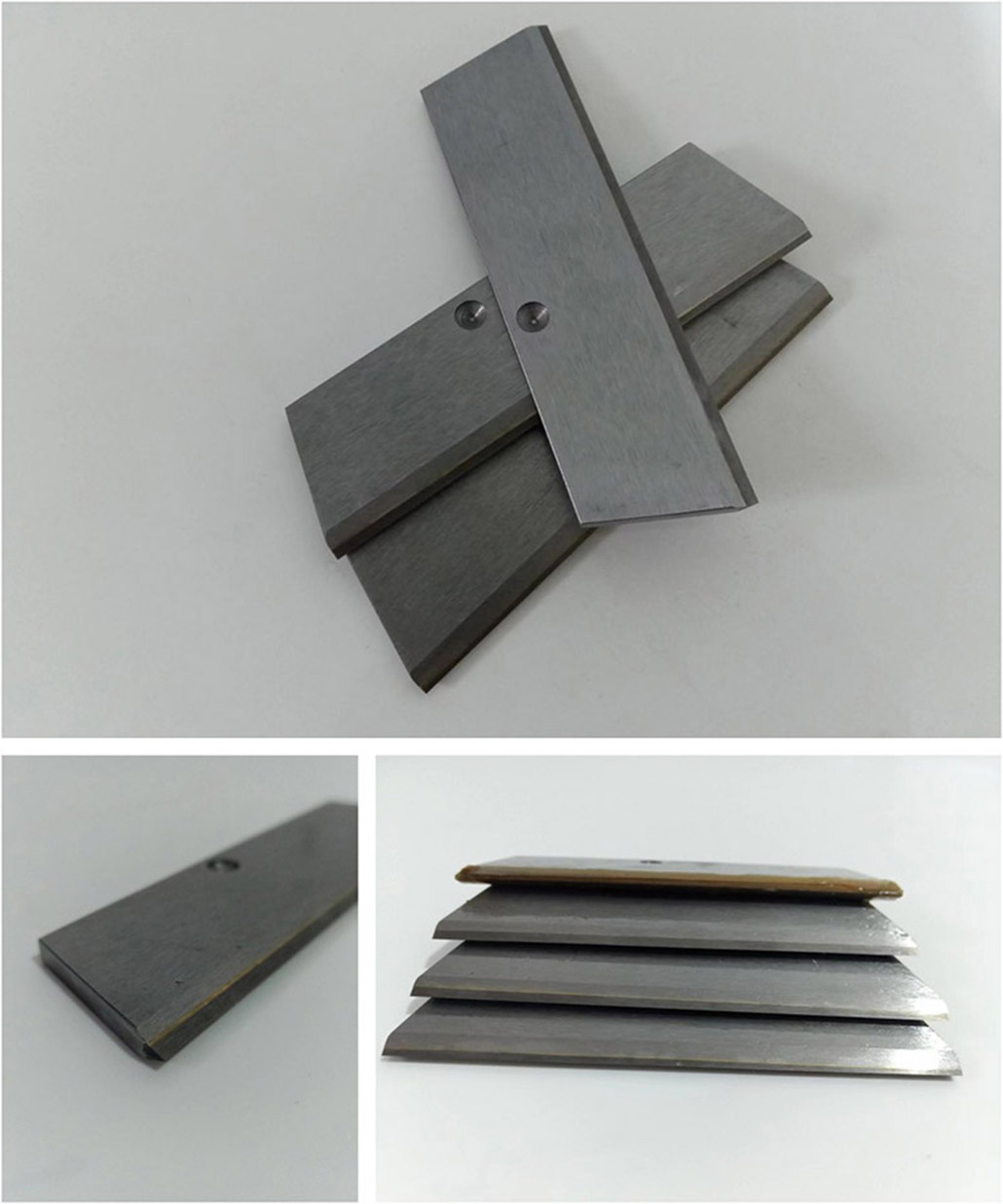

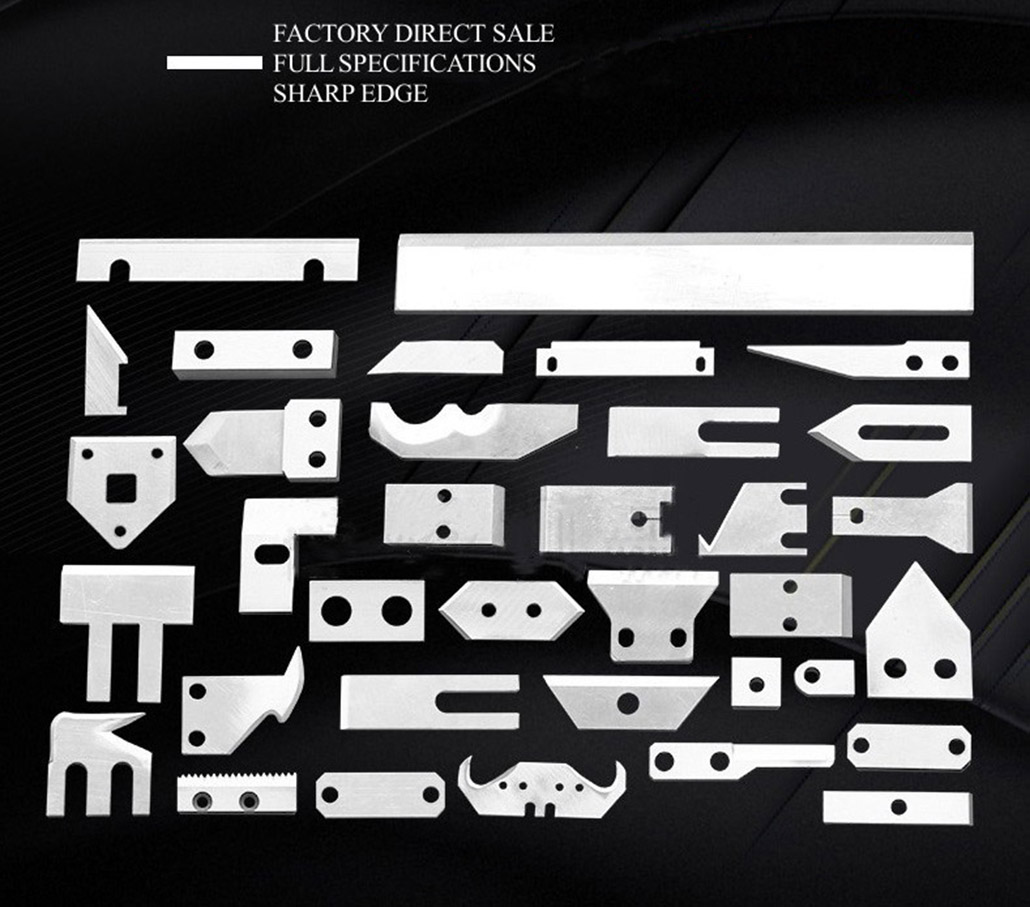

Blade e hlophisitsoeng e khethehileng ea carbide e khethehileng

Carbide polasetiki le rabara lithupa

Carbide Places

Carbide o ile a roala thipa

Cebide Climang li-skid

Carbide Strip Blade le lesoba

Allisage

• Ho feta lilemo tse 15 ho kenya boiphihlelo ba ho etsa lintho tse ngata le lisebelisoa tse tsoetseng pele le theknoloji.

• Mofoko o phahameng le khanyetso ea mocheso; Bophelo bo botle ba lits'ebeletso tse telele tsa tšebeletso ea tšebeletso.

• Ho nepahala ho phahameng, ho khaola ka potlako, ho hloka botsitso le ts'ebetso e tsitsitseng.

• Bokaholimo ba pohing; E feta tekano e bobebe e fokotsang nako e nyane.

Likopo

Li-trungsten carbide li ne li kuta le ho kuta ha ho paka, ho itšeha le mechini e sa feleng, indasteri, koae le matloana.

Taolo ea rona ea boleng

Leano la boleng

Boleng ke moea oa lihlahisoa.

Taolo ea tšebetso ka kotloloho.

Zero o mamella bofokoli!

Ho fetisa setifikeiti sa Iso9001-2015

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe