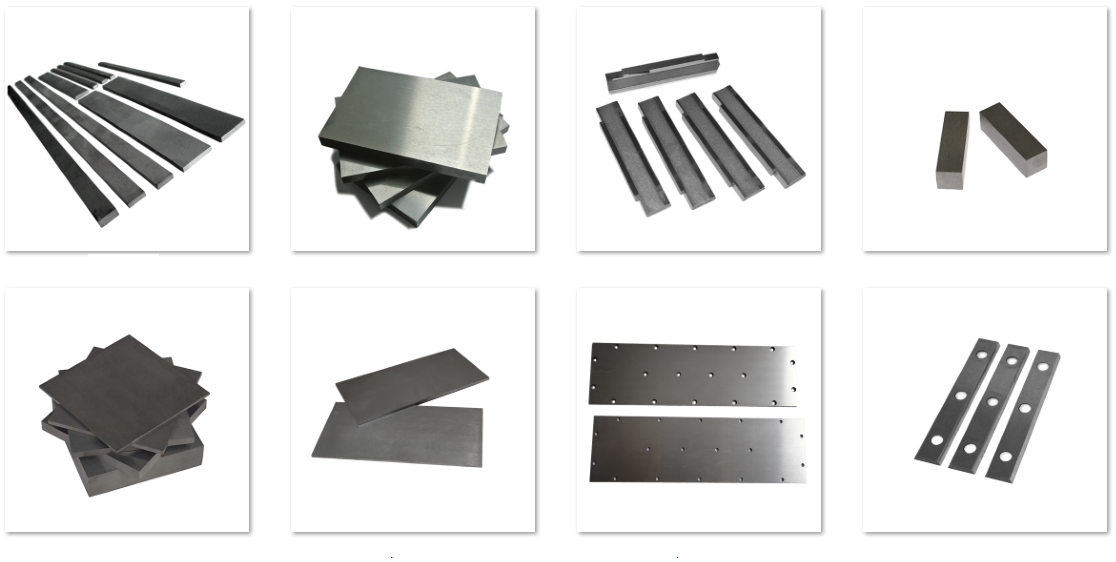

Thongsten carbide poleiti ea matloana bakeng sa hlobo

Tlhaloso

Please ea Carbide ea Carbide e nang le kamano e ntle le e matla e hanyetsang, e ka sebelisoa ho lisebelisoa tsa habo bona.

Plate ea carbide ea tungsten e sebelisoa haholo ho indasteri ea elektroniki, sethuthuthu

Hobaneng u khetha thepa ea carbide ea tungsten?

Cartide e kopaneng e na le letoto la thepa e ntle e kang ho hanyetsa ka thata, haholo ho hanyetsa, matla a mocheso, e ntse e sa fetohe, 'me e ntse e le thata ho 1000. Ka hona, e sebelisoa ka bongata mochining. Melemo ea 'mele ea mafura a tungsten e bonyane makhetlo a 3 ea tšepe. E ka etsoa ka mefuta eohle ea lipolanete tsa carbisi.

Linepe tsa Resort

Tlhahisoleseling e tloaelehileng ea boholo: (OEM e amoheloa)

| Botenya | Bophara | Bolelele |

| 1.5-2.0 | 150 | 200 |

| 2.0-3.0 | 200 | 250 |

| 3.0-4.0 | 250 | 600 |

| 4.0-6.0 | 300 | 600 |

| 6.0-8.0 | 300 | 800 |

| 8.0-10.0 | 300 | 750 |

| 10.0-14.0 | 200 | 650 |

| > 14.0 | 200 | 500 |

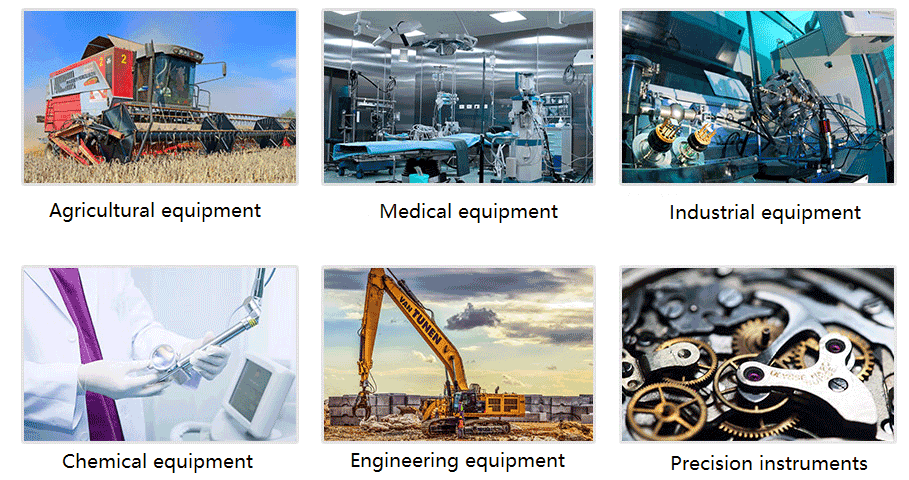

Likopo

Chuangru's Combide Clatide Platation Futeture Futeture

1. Botsitso ba botle ba mollo le mocheso o phahameng oa mocheso.

2. Mocheso o phahameng oa mocheso ka lithemparetjha tse phahameng.

3..

4. Ho na le boits'oaro bo phahameng bo phahameng.

5. Bokhoni ba taolo e ntlehali ea oxidation.

6. Crosisation ho hanyetsa mochesong o phahameng.

7. Ho hanyetsa ka mokhoa o motle haholo ho lik'hemik'hale.

8. Ho hanyetsa haholo ho hanyetsa.

9. Bophelo bo bolelele ba lits'ebeletso.

Rea u amohela ho ikopanya le rona nakong efe kapa efe!

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe