Li-Udbide tsa Khotso tsa Tungas

Tlhaloso

Lits'oants'o tsa carbide tsa carbide li sebelisoa hohle bakeng sa lisebelisoa tsa boleng bo phahameng ba koloi e phahameng joalo ka li-custlings tsa milling, lijalo tsa ho qetela, li-midrs, mokhanni, mekoallo; ho tsitsipana, ho lekanya lisebelisoa le lijalo tse fapaneng tsa roll.

Tlhaloso ea lithunya tsa carbide ea tungsten

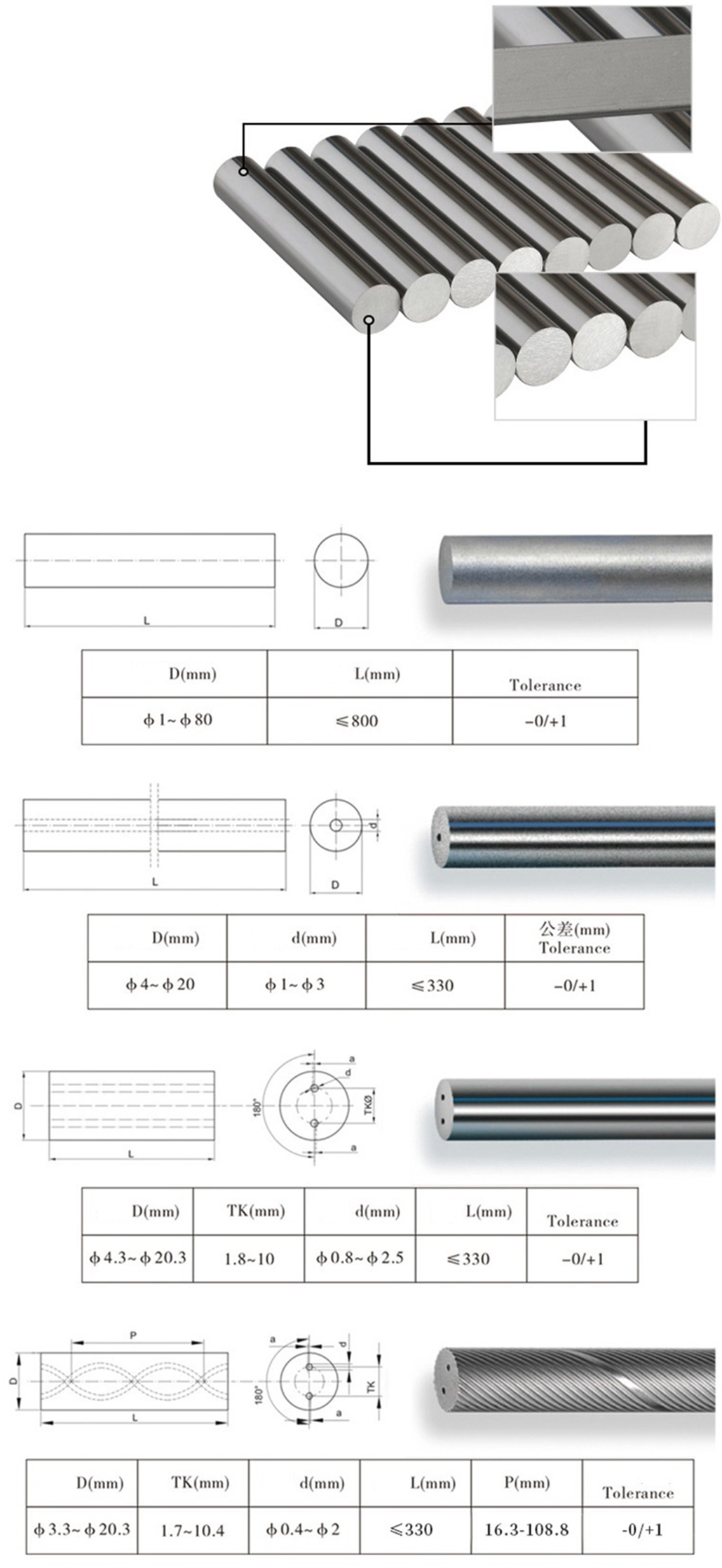

Mefuta ea lithupa tsa Carbime:

Setifi se tiisitsoeng sa carbide rod & carbide molatsoana o se na letho

Carbime molamu o otlolohileng oa CUREATLE CULLATLE

Carbiside Rods ka masoba a mabeli a otlolohileng a otlolohileng

Li-carbide tsa Carbiside ka masoba a mabeli a booatla.

Mekhabiso e fapaneng ea fumaneha, lits'ebeletso tsa tumellano lia amoheleha

Keletso

| Sehlopha sa ISO | Boholo ba lijo-thollo (μM) | CO% | Hardness (HRA) | Mabenyane (g / cm3) | TRS (N / MM2) | Liindasteri tsa Ts'ebeliso | Kopo |

| K05-K10 | 0.4 | 6.0 | 94 | 14.8 | 3800 | Indasteri ea PCB | Tšepe e se nang thuso, e seng ea tšepe ea tšepe le li-cros |

| K10-k20 | 0.4 | 8.5 | 93.5 | 14.52 | 3800 | Pcb e sehiloeng e sehiloeng; Liphoso tsa polasetiki le tse phahameng haholo | |

| K10-k20 | 0.2 | 9.0 | 93.8 | 14.5 | 4000 | Indasteri ea hlobo | Lintho tse phahameng tsa thata |

| K20-k40 | 0.4 | 12.0 | 92,5 | 14.1 | 4200 | 3c le indasteri ea bold | Seha tšepe (HRC45-55) Alfalon le Ti Lelloy |

| K20-k40 | 0.5 | 10.3 | 92.3 | 14.3 | 4200 | Steel Stainle le Mohala oa mocheso, Iron | |

| K20-k40 | 0.5 | 12.0 | 92 | 14.1 | 4200 | Steel Holfele, ho na le thepa ea tšepe le e phahameng haholo | |

| K20-k40 | 0.6 | 10.0 | 91.7 | 14.4 | 4000 | Steel Holsloy le Alloy Alloy, Iron ea Iron | |

| K30-k40 | 0.6 | 13.5 | 90.5 | 14.08 | 4000 | Ho nepahala ho shoa | Ho etsa selikalikoe |

| K30-k40 | 1.0-2.0 | 12.5 | 89.5 | 14.1 | 3600 | Ho etsa puch e bataletseng | |

| K30-k40 | 1.5-3.0 | 14.0 | 88.5 | 14 | 3700 |

Likaroloana

● 100% CARIGHTIT TANGSTER LITLHAKISO TSA BOPHELO

● Libaka tsa sekolo le lefatše li fumaneha ka bobeli

● boholo bo fapaneng le limaraka; Litšebeletso tsa tumellano

● Ho kuta maikutlo le ho tšoarella

● Litheko tsa tlholisano

Lethathamo la carbide ea cartide bakeng sa ho ba le lisebelisoa

FEANSTON STEUSTON STEEL RODS

Bartered carbide Round Bar

Carbide ea carbide Micro Rod

Sekoti se se nang letho la mokokotlo oa mokokotlo oa tungsten

Moqapi oa Carbide Rod

Monyetla

● Boholo bo tsoa ho 0,2μμm-0.8μm, thata 91ra-95hra. Ka tlhahlobo e matla ea boleng le ho netefatsa boleng bo lekanang batch e 'ngoe le e' ngoe.

● E ngotsoe ho Carbiside Surbide e fetang lilemo tse 10, e nang le mela e ikhethang ea lithupa tse tiileng tsa carbiside le molamu oa masoba.

● Joaloka Moetsi oa ISO, re sebelisa lisebelisoa tsa boleng bo holimo ho netefatsa boleng le ts'ebetso e ntle ea lithupa tsa rona tsa carbisi.

● Rod ea Carbisi e ho etsa lisebelisoa tse remaneng. Lisebelisoa tse entsoeng ho rona li na le ts'ebetso e telele ea mochini o tsitsitseng oa mochini.

Kopo

Liphallelo tsa carrode tse ngata, tse kang pampiri, lisecing, le mechini, petroleum, indasteri ea tšepe. Le indasteri ea koloi le lithuthuthu, indasteri ea lithuthuthu, indasteri ea compressor, indasteri ea Aerospace, indasteri ea ts'ireletso.

Taolo ea rona ea boleng

Leano la boleng

Boleng ke moea oa lihlahisoa.

Taolo ea tšebetso ka kotloloho.

Zero o mamella bofokoli!

Ho fetisa setifikeiti sa Iso9001-2015

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe