Konopo ea carbide spirical konopo

Tlhaloso

Meno a qapiloeng a cartime tse halikiloeng a sebelisoa haholo lisebelisoa tsa lesela la lehloa bakeng sa ho tlosa lehloa le lehloa. Ntle le moo, menoana ea maoto ea carbide ea carbide e sebelisoa hantle ka ho rema lisebelisoa le mechini, tlhokomelo ea methapo ea mashala. Meno e meholo ea carbide ea carbide e sebelisitsoeng liqhomane e sebelisoa haholo e le lisebelisoa tsa ho chesoa ke mearo ea meepo, merafong le meepo e mengata.

Kopo

Konopo ea cartide e halikiloeng e sebelisoa haholo ka lebaleng la oli le ho tlosa lehloa, lehloa la lehloa kapa lisebelisoa tse ling ka lebaka la thepa ea bona e ikhethang. Ho latela mechini e fapaneng ea likhomo, e kang cone ea likhomo, meno a ho cheka a gebide e fapaneng, boemo ba bolo ea P-cute, boemo ba X-cine. Ho tsitsa le theknoloji e phahameng ho tiisa boleng bo phahameng ba lihlahisoa tsa rona, hangata meno a betlise a sebelisoa e le lisebelisoa tsa ho chencha, mechini ea mechini ea maoto le tseleng. Meno ea likoloi ea carbide ea carbide e boetse e sebelisoa haholo e le lisebelisoa tse sa tsotelleng tsa morao-rao tsa ho fihlela morao, meepong ea ho opeloa ke litoropo. Ntle le moo, e boetse e sebelisoa e le ntho e loketseng haholo bakeng sa sesebelisoa sa Drill se Kotuhileng kapa se tebileng sa ho palama sekepe se tebileng.

Likaroloana

Cartide Card ke lisebelisoa tse ntle ho hlahisa meno a bolotsana a kopaneng a sebelisoang haholo indasteri ea hard hammer.

Konopo ea Carbide e sebelisoa haholo ka meepo, e huleloa le ho itšeha ka lebaka la bo boholo ba bona bo phahameng. Li ka sebelisoa le tsona tse boima li-nutscator tse boima.

Keletso

| Keletso | Letsoalog / cm3 | TRR MPA | Ho thataHRA | Kopo |

| CR4C | 15.10 | 1800 | 90.0 | Haholo-holo e sebelisoa bakeng sa ho kuta lisebelisoa tse thata le tse bonolo tsa ho khanna. |

| Cr6 | 14.95 | 1900 | 90.5 | Ha li-coal tsa Coal tsa motlakase tsa motlakase, litšoantšo tsa mashala, li-petroleum Cone e loma le li-grapet e bobebe. |

| Cr8 | 14.80 | 2200 | 89.5 | E sebelisoa e le ho lemala sefuba, ho lora ha motlakase, litšoantšo tsa mashala, peterole ea peroleum le ho lema le maoto le bolo ea maoto. |

| CR8C | 14.80 | 2400 | 88.5 | Haholo e sebelisoa joalo ka leino le bohareng le tšusumetso e nyane hanyane le joalo ka sehlahla se behang ka seretse sa ho iphetetsa. |

| Cr11c | 14.40 | 2700 | 86.5 | Boholo bo sebelisoa ka har'a meropa e nang le tšusumetso le ka har'a cone ea makhopho ho khaola meno a thepa e phahameng haholo. |

| CR13C | 14.2 | 2850 | 86.5 | Haholo-holo e sebelisoa bakeng sa ho khaola meno a bal ea maoto le lisebelisoa tse matla tsa ho senya Rotary |

| CR15C | 14.0 | 3000 | 85,5 | E sebedisoang bakeng sa oli ea oli ea oli le e bonolo le e bonolo le e bohareng e bothileng ka thata. |

Boholo

OE a amoheloang.

Sesebelisoa se tloaelehileng sa konopo ea tungsten carbide e ka tlase:

| Mofuta | Boholo (limilimithara) | ||||||||

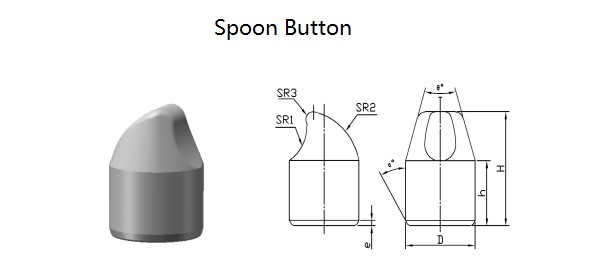

| D | H | h | Ɵ ° | SR1 | SR2 | SR3 | α α | e | |

| S1015 | 10.25 | 15 | 9.8 | 50 | 12 | 20 | 3 | 18 | 1.2 |

| S1116 | 11.3 | 16.5 | 10.2 | 50 | 15 | 24 | 3 | 18 | 1.2 |

| S1218 | 12.35 | 18 | 11 | 36 | 20 | 25 | 2.5 | 18 | 1.5 |

| S1399 | 13.35 | 19 | 12 | 50 | 15 | 20 | 3 | 18 | 1.5 |

| S1421 | 14.35 | 21 | 12.5 | 40 | 12 | 25 | 3 | 18 | 1.8 |

| S1521 | 15.35 | 21 | 12 | 50 | 20 | 30 | 3 | 18 | 1.8 |

| S1624 | 16.35 | 24 | 13 | 30 | 15 | 20 | 3 | 18 | 2 |

| S1877 | 18.25 | 27 | 14.5 | 30 | 18 | 20 | 3 | 18 | 2 |

| Mofuta | Boholo (limilimithara) | |||||||

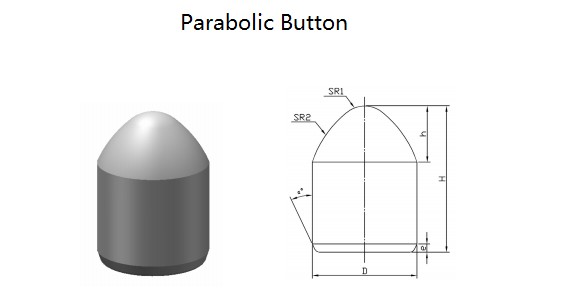

| D | H | SR1 | SR2 | h | α α | Β | e | |

| D0711 | 7.25 | 11 | 1.9 | 8.7 | 3.9 | 20 | 25 | 1.6 |

| D0812 | 8.25 | 12 | 2.5 | 9 | 4.5 | 20 | 25 | 1.6 |

| D0913 | 9.25 | 13 | 2.5 | 11 | 5 | 20 | 25 | 1.8 |

| D1015 | 10.25 | 15 | 3.2 | 11.8 | 5 | 20 | 25 | 1.8 |

| D1117 | 11.3 | 17 | 3 | 13.5 | 6 | 20 | 25 | 1.8 |

| D1218 | 12.35 | 18 | 3 | 12 | 6.5 | 20 | 20 | 2 |

| D1319 | 13.35 | 19 | 3.5 | 13.5 | 7.1 | 20 | 20 | 2 |

| D1420 | 14.35 | 20 | 4.2 | 13 | 8 | 20 | 20 | 2 |

| Mofuta | Boholo (limilimithara) | ||||||

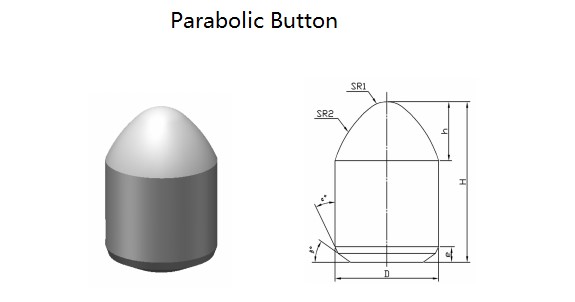

| D | H | SR1 | SR2 | h | α α | e | |

| D0711 | 7.25 | 11.0 | 1.9 | 8.7 | 3.9 | 18 | 1 |

| D081na | 8.25 | 12.0 | 2.5 | 9 | 4.5 | 18 | 1 |

| D0913A | 9.25 | 13.0 | 2.5 | 11 | 5 | 18 | 1 |

| D1015a | 10.25 | 15.0 | 3.2 | 11.8 | 5 | 18 | 1.2 |

| D1117a | 11.3 | 17.0 | 3 | 13.5 | 6 | 18 | 1.2 |

| D1218a | 12.35 | 18.0 | 3 | 12 | 6.5 | 18 | 1.5 |

| D13199 | 13.35 | 19.0 | 3.5 | 13.5 | 7.1 | 18 | 1.5 |

| D1420a | 14.35 | 20.0 | 4.2 | 13 | 8 | 18 | 8 |

| Mofuta | Boholo (limilimithara) | |||||

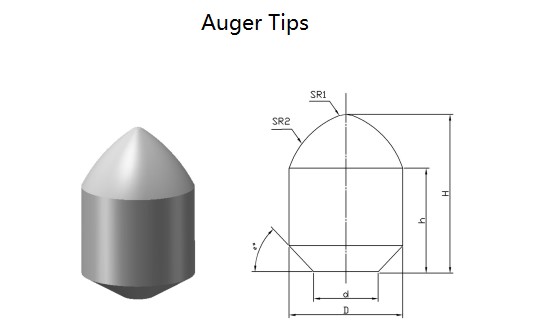

| D | d | H | h | SR1 | SR2 | |

| JM1222 | 12 | 3.0 | 22 | 15 | 1.5 | 26 |

| JM1425 | 14 | 4.0 | 25 | 17 | 1.5 | 26 |

| JM1625 | 16 | 5.0 | 25 | 16 | 1.5 | 26 |

| JM1828 | 18 | 5.0 | 28 | 18 | 1.5 | 26 |

| JM2428 | 24 | 10.1 | 28 | 16 | 2 | 36 |

| JM2534 | 25 | 18.0 | 34 | 20 | - | 25 |

| Mofuta | Boholo (limilimithara) | |||||

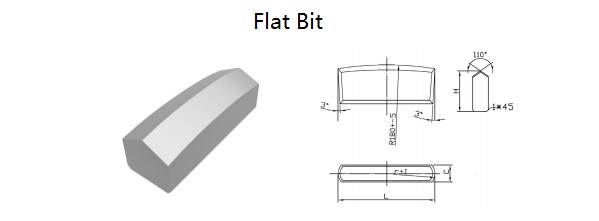

| L | H | C | r | |||

| A | B | C | ||||

| K026 | 26 | 18.0 | 15 | 12.5 | 8 | 13 |

| K028 | 28 | 18.0 | 15 | 12.5 | 8 | 14 |

| K030 | 30 | 18.0 | 15 | 12.5 | 8 | 15 |

| K032 | 32 | 18.0 | 15 | 12.5 | 8 | 16 |

| K034 | 34 | 18.0 | 15 | 12.5 | 8 | 17 |

| K036 | 36 | 18.0 | 15 | 12.5 | 10 | 18 |

| K038 | 38 | 18.0 | 15 | 12.5 | 10 | 19 |

| K040 | 40 | 18.0 | 15 | 12.5 | 10 | 20 |

| K042 | 42 | 18.0 | 15 | 12.5 | 10 | 21 |

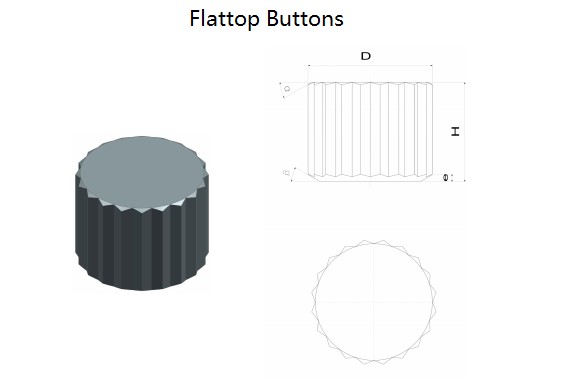

| Mofuta | Boholo (limilimithara) | ||||

| D | H | t | α α | e | |

| Mh0806 | 8 | 6.0 | 0.5 | 25 | 1.1 |

| MH1008 | 10 | 8.0 | 0.5 | 25 | 1.9 |

| MH1206 | 12 | 6.0 | 0.5 | 25 | 1.9 |

| MH1208 | 12 | 8.0 | 0.5 | 25 | 2.5 |

| MH1410 | 14 | 10.0 | 0.5 | 25 | 2.5 |

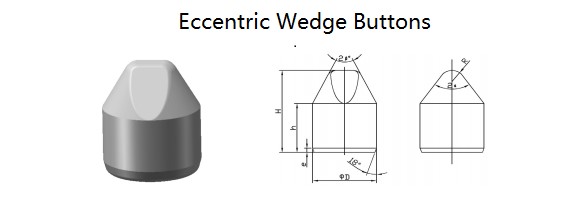

| Mofuta | Boholo (limilimithara) | |||||||

| D | H | h | R | r | α α | Β | e | |

| X0810 | 8 | 10 | 6.5 | 2 | 1.8 | 45 | 22.5 | 1.5 |

| X1011 | 10 | 11 | 7 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1013 | 10 | 13 | 9 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1115 | 11 | 15 | 8 | 2.8 | 2.5 | 22.5 | 22.5 | 1.5 |

| X1215 | 12 | 15 | 9 | 3 | 2.5 | 45 | 22.5 | 1.5 |

| X1217 | 12 | 17 | 10.5 | 3.5 | 3 | 35 | 20 | 1.5 |

| X1418 | 14 | 18 | 10 | 3.5 | 3 | 45 | 22.5 | 1.5 |

| X1420 | 14 | 20 | 11 | 2.7 | 3 | 35 | 22.5 | 1.5 |

| X1520 | 15 | 20 | 12 | 3 | 3 | 40 | 22.5 | 1.5 |

| X1621 | 16 | 21 | 11 | 2.6 | 3 | 35 | 22.5 | 2 |

| X1623 | 16 | 23 | 12 | 3 | 3.5 | 30 | 18 | 2 |

| X1721 | 17 | 21 | 13 | 4 | 3.5 | 40 | 22.5 | 2 |

| X1724 | 17 | 24 | 13 | 3.5 | 3.5 | 30 | 22.5 | 2 |

| X1929 | 19 | 29 | 17 | 4 | 3 | 30 | 15 | 2 |

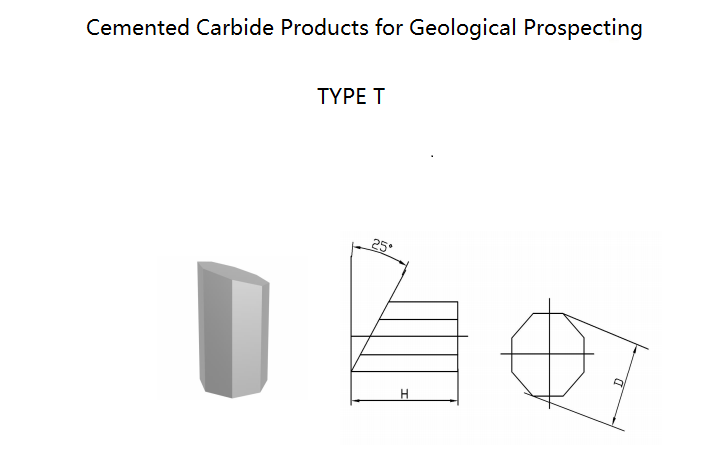

| Mofuta | Boholo (limilimithara) | |

| D | H | |

| T105 | 5 | 10 |

| T106 | 7 | 10 |

| T107 | 7 | 15 |

| T109 | 9 | 12 |

| T110 | 10 | 16 |

Melemo ea rona

Kotlo e meholo ea cartide e halikiloeng e na le matla a ho hanyetsa le ho thatafala, 'me e na le lebelo le phahameng ho feta lihlahisoa tse tšoanang. Bophelo bo se nang mohloa bo ka bang ka makhetlo a 5-6 ha feela ba le bophara bo lekanang, bo leng molemo ho boloka lebelo la ho sebetsa ka thata le ho potlakisa lebelo la boenjiniere.

Bakeng sa lintlha tse ngata ,nce o amohelehile ho ikopanya le rona nakong efe kapa efe!

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe