Roala likhoele tsa khaba ea tungsten tuko bakeng sa lisebelisoa tsa motlakase

Tlhaloso

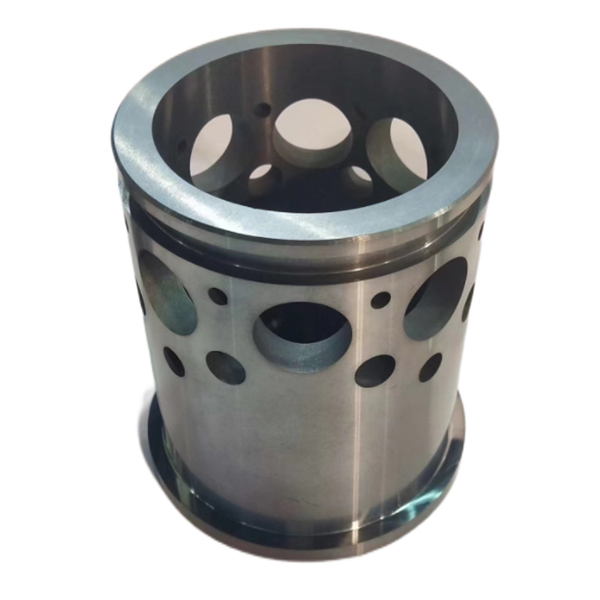

TheLikhanya tsa carbide carbideli sebelisoa haholo valves ho laola molumo oa mokelikeli le khatello ka nepo. Sehlopha se tummeng ka ho fetisisa bakeng sa mabokose a Carbide a kopaneng a CR05A le CR06n, e entseng hantle ka ts'ebeliso ea li-valve. Boholo ba sehlahisoa bo laoloa ka nepo le boemo ba lesoba ho nepahetse ho fihlela litlhoko tsa thuto e sebelisoang.

Taolo ea ho fana ka polasetiki ea ho laolaBakeng sa tokiso e pharalletseng ea Belhead ha e sa sireletseha ka oli le khase ea khase, ho qoba ho hlahlobisisa lisebelisoa tsa taolo ea lisebelisoa.

Lihlahisoa le theknoloji e tsoang Zhuzhou Chuangruii li sebelisoa haholo masimong a oli le khase, boenjiniere ba lik'hemik'hale, Aerospace ea nyutlelie le Aerospace. Haholo-holo e sebelisoang haholo maemong a thata a thata e kenyelletsa apsion e matla, khoholeho ea tšeho, mocheso o phahameng, khatello e phahameng le tšusumetso e matla. Bareki ba rona ba ka sehloohong ke lik'hamphani tsa lehlohonolo. Zhuzhou Chuangrui ke likhoebo tse etellang pele tsa bokahohleng tsa li-crabisi tse sa khaotseng le tsa 'mala o sa sebetseng hantle le mekhoa e amanang le thepa ea mochini.

Mefuta

Li-chuangru li chuangru li ne li le chuangru li apara likarolo tse fapaneng, tse sebetsoang le ho etsoa ka thepa e phahameng ea pherekano. E na le litšobotsi tsa khanyetso e phahameng ea mocheso, khanyetso ea ho hanyetsa, ho hanyetsa ka mokhoa o phahameng, ho nepahala haholo ho etsa likarolo tsa indasteri ea oli le ea khase. Li-chuangru li ne li le chuangru tse halikiloeng tsa carbide carbide li fumaneha ka mefuta e mengata ea methapo le boholo ba kopo ea lintho tse boima.

Monyetla

● Na setifikeiti sa Setifikeiti sa Asp9100, Setifikeiti sa Apifi, ISO9001: 2015.

● Ka thuto e khethehileng ea methapo ea kutlo.

● Karolo e telele e fetohang e phahameng, selikalikoe se telele se sebetsang .100% Lihlahisoa tsa Tlhaho.

● E khethiloe joalo ka litlhoko tsa hau.all hlobo e entsoeng ka tlung.

● Fetshe e amohelang feme ea indasteri ea oli le ea tlhaho e kholo.

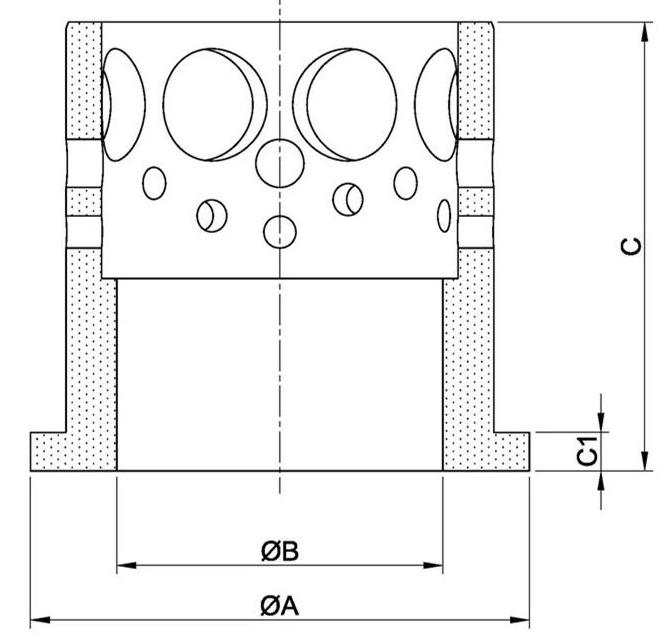

| Φma | Φb | C |

| 70.8 | 50.8 | 104 |

| 95.3 | 76.2 | 111 |

| 155.5 | 101.6 | 140 |

Tlhahisoleseling ea lintho tse latelang ka tsela e latelang:

| Limaraka | LITLHAKISO TSA 'Mele | Kopo e kholo le litšobotsi tse kholo | ||

| Ho thata | Letsoalo | TRS | ||

| HRA | g / cm3 | N / mm2 | ||

| CR05A | 92.0-93.0 | 14.80-15.00 | ≥2850 | E loketse ho hlahisa likarolo tse sebelisoang bakeng sa pompo e thibetsoeng ka oli, ntlha ea valman le setulo sa valve ka lebaka la ho hanyetsa ha ho hanyetsa haholo |

| CR06n | 90.2-91.2 | 14.80-15.00 | ≥2650 | E loketse ho hlahisa li-spoweve le mahaeng tse sebelisoang indastering ea oli le khase ka lebaka la ho hanyetsa sehatelo le khomphutha ea khoholeho |

Line ea Lihlahisoa tsa Baemeli

● Litšoele le li-valve tsa li-val

● Li-Ue Rings

● Drill e nyane, Likokoana-hloko, Liphoso

● Karolo ea lisebelisoa tsa MWD, lits'o tsa lisebelisoa tsa motlakase

● Likomo tsa TC, PDC e li apara

● Likhetho tsa ho laola likarolo tsa Doling

● Lits'oants'o tsa maiketsetso tsa pompo

Lisebelisoa tsa Production

Ho tsitsa

Spray o omileng

Tobetsa

PUP PUSELETSO

Semi-tobetsa

Sehloela se Sikulang

Lisebelisoa tsa ts'ebetso

Ho cheka

Terata e kuta

E otlolohileng slinding

Ho tsitsa bokahohleng

Ho thellisa sefofane

Mochini oa CNCA Carting

Sesebelisoa sa tlhahlobo

Boima mitha

Ramente

Tekanyo ea Karolo ea Quadation

Seletso ea makenete ea cobattic

Microscope ea tšepe